NEOECO NCT-SJ81 Dual Action Airbrush Instruction Manual

- June 13, 2024

- NEOECO

Table of Contents

INSTRUCTION MANUAL

Dual-Action Airbrush

NCT-SJ81  IMPORTANT:

Read before using.

IMPORTANT:

Read before using.

WWW.neoeco-airbrush.com

Explosion Disassembly Diagram

NOET: The drawing does not illustrate the complete structure/scope of

delivery of the instrument.

NOET: The drawing does not illustrate the complete structure/scope of

delivery of the instrument.

Parts List

1 Needle cap

2 Air cap

3 Nozzle 0.3mm

4.1 9¢c¢ silver cup

4.2 20cc plastic cup

4.3 40cc plastic cup

5 Airbrush Stem

6 Lever with dual action

7 Neelde chuck

8 Spring

9 Spring case

10 Tension adjustment

11 Needle securingnut

12 End piece

13 Ajustment knob ring

14 0.3mm needle

15 Intet valve

16 MAC valve

Spare Parts

0.2mm Air cap 1,0.2mm Nozzle 1, 0.2mm Needle » 1; 0.5mm Air cap + 1, 0.5mm Nozzle + 1, 0.5mm Needle + 1, 8pcs O ring set *1

FAQ

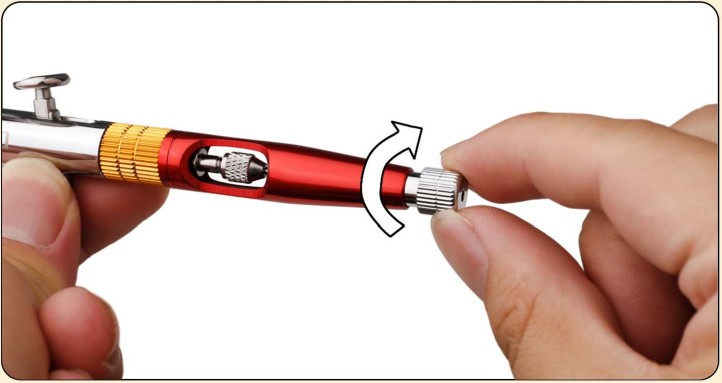

Q: How to remove the tension adjustment ring off from the airbrush?

A: Use the adjustable spanner in a counterclockwise motion to loosen and

unscrew it carefully.

Q:

Can i use lacqoer thinner or acetone to thin paint or clean the plastic cups

and airbrush without damaging them?

Q:

Can i use lacqoer thinner or acetone to thin paint or clean the plastic cups

and airbrush without damaging them?

A: You can clean the airbrush using lacquer thinner or acetone, but avoid

putting the seats into these solvents or immersing the airbrush in them, as it

may damage the seals, When deating with plastics, quickly flush them with the

cleaner and ensure thorough washing if lacquer thinner or acetone is used, as

they are too powerful for plastics.

Q: What types of paints can i use in my airbrush?

A: Airbrushes are compatible with a wide range of paints, as long as they have

a suitable consistency for airbrushing. Here are some common types of paints

that can be used in an airbrush: Water-Based Acrylic Paints, Solvent-Based

Enamel Paints, Lacquer-Based Paints, Oil-Based Paints, Ink and Dye-Based

Paints, etc. Different paints may require specific airbrush thinner mediums of

additives to achieve the optimal consistency and prevent clogging or tip dry.

Operation & Function

Press lever down to activate air

Presss lever backwards to activate paint

Presss lever backwards to activate paint  Turn

to set the desired trigger sensitivity Turn the knob to set how far the trigger can

be pulled back

Turn the MAC valve to adjust the air flow

Turn the MAC valve to adjust the air flow

First Exercise

- Create dots, lines, and dashstrokes

https://neoeco-airbrush.com/a/qrcode-rsi/orsk5bbRLh9vFS

https://neoeco-airbrush.com/a/qrcode-rsi/orsk5bbRLh9vFS - Embark on Your First Airbrush Project!

https://neoeco-airbrush.com/a/qrcode-rsi/ygC6HwNNCivhZW

https://neoeco-airbrush.com/a/qrcode-rsi/ygC6HwNNCivhZW

Cleaning

STP 1. Add cleaner into the fluid cup.

STP

2. Block the needle cap to get the back flow.

STP

2. Block the needle cap to get the back flow.  STP 3. Spray out the paint, and

repeat steps 1-3 several times.

STP 3. Spray out the paint, and

repeat steps 1-3 several times.  STP 4. Terminate the compressed air supply.

Unscrew the end piece and needle secure nut.

STP 4. Terminate the compressed air supply.

Unscrew the end piece and needle secure nut.  STP 5. Pull the needle and clean

with a cloth or airbrush wipe.

STP 5. Pull the needle and clean

with a cloth or airbrush wipe.  STP 6. Detach the cup and clean it.

STP 6. Detach the cup and clean it.  STP

7. Unscrew the needle cap and clean with a cotton bud.

STP

7. Unscrew the needle cap and clean with a cotton bud. STP 8. Remove the nozzle

and push any paint residue carefully out of the interior with a

needle.

STP 8. Remove the nozzle

and push any paint residue carefully out of the interior with a

needle. STP 3. Screw the nozzle on, then fasten the needle cap into

position. Press the lever down and carefully insert the needle until it

reaches the stop. Finally, secure the needle securing nut and end piece Into

position.

STP 3. Screw the nozzle on, then fasten the needle cap into

position. Press the lever down and carefully insert the needle until it

reaches the stop. Finally, secure the needle securing nut and end piece Into

position. Cleaning airbrush tutorial

Cleaning airbrush tutorial

https://neoeco-airbrush.com/a/qrcode-rsi/FRHIP1mHrKsOhA

https://neoeco-airbrush.com/a/qrcode-rsi/FRHIP1mHrKsOhA

Further Maintenance Instructions

Avold immersing the entire instrument in solvent. Instead, occasionally apply

a small amount of thinned oil to the lever mechanism. Ensure that the needle

tip and nozzle remain free of oll and grease, as these can affect the spraying

performance. Components like the needle, nozzle, and seals are subject to wear

and should be replaced when necessary. For added convenience, nozzle sets and

fluid cups are available in various sizes to facilitate easy conversion.

To achieve improved spray performance, consider polishing the needle for a

smoother finish.

For a detailed tutorial on this process, please check the page beside:<https

://neoeco-airbrush.com/a/qrcode-rsi/IA4MbeoWIQm5sX>

Accessories

Moisture Trap

Used to prevent moisture and condensation from reaching the airbrush, ensuring

a steady and consistent airflow. Can be installed between the air source and

the airbrush itself. By using a moisture trap, airbrush artists can maintain a

dry and reliable air supply, reducing the risk of paint clogs, sputtering, or

other iIssues caused by excess moisture in the air.

Quick Disconnect Coupler

used to swiftly and easily connect or disconnect an airbrush from an air

hose.

Consists of two parts: one attaches to the airbrush and another attaches to

the air hose. When you need to connect the airbrush to the hose, simply align

the two parts and push them together until they click into place. To

disconnect, push back the sleeve on the coupler, and 1t will release the

connection.

Airbrush Cups

Both 20cc and 40cc fluid cups are available for exchange, providing

versatility in your airbrushing projects. Opt for the larger cup sizes when

tackling bigger tasks or covering larger areas, as they minimize the need for

frequent refills, ensuring uninterrupted and efficient work.

Replacement Needles And Nozzles

We offer replacement needles and nozzles in two sizes: 0.2mm and 0.5mm. These

replacements ensure you have the right tools for various painting tasks. The

0.2mm option Is perfect for intricate detailing and fine lines, while the

0.5mm option is ideal for broader coverage and larger areas. Having these

replacement parts on hand allows you to maintain peak performance and achieve

the desired results with your airbrush. Air Hose

It serves as the link between the airbrush and the air source, facilitating

the flow of air essential for proper paint spraying. With a length of 6ft,

this hose features a 1/8 inch BSP connector on one end and a 1/4 inch BSP

connector on the other. Should you require both ends to be 1/8 inch BSP,

simply unscrew the 1/8 to 1/4 adapter, and you’ll have both sides with 1/8″

BSP fittings.

Cleaning Needles And Brushes

Cleaning needles are thin, needle-like tools used to remove dried or stubborn

paint particles from the nozzle and airbrush components. Cleaning brushes are

small, soft-bristled brushes designed to clean various parts of the airbrush,

such as the paint cup, airbrush body, and other hard-to-reach areas.

Gold Reamer

Used for cleaning and maintaining the delicate parts of an airbrush,

particularly the nozzle and needle. It I1s designed to gently remove dried

paint, debris, or any obstructions that may cause clogs or affect the

airbrush’’s performance.

Neelde Cap

The primary function of the needle cap is to protect the delicate needle tip

from damage or bending during use and handling. It i1s essential to keep the

airbrush needle cap clean and free from paint buildup or debris, as any

obstructions can affect the spray pattern and overall airbrush performance.

Small Wrench

Designed specifically to assist In removing and installing the nozzle of an

airbrush. It 1Is a compact and precision-engineered wrench that fits snugly

around the nozzle, providing the necessary leverage to loosen or tighten it

securely.

Replacement seals

Used to maintain airtight connections and prevent air and paint leakage In

an airbrush.Over time, seals can degrade due to usage or exposure to certain

solvents, so having replacement seals on hand 1s important for avolding

unexpected i1ssues during airbrushing sessions. Properly maintaining these

seals will help you achieve consistent and high-quality results with your

airbrush.

Troubleshooting

Not Spraing

Loose needle secure nut| |Ensure that the needle is properly inserted and

tightened.

---|---

Improper air pressure| Ensure that your air compressor Is providing

sufficient pressure.

Paint too thick| Dilute the paint to skim milk or light cream consistency.

Test the consistency on a palette or scrap surface before using it in the

airbrush.

Clogged nozzle| Disassemble the airbrush and clean each component thoroughly

with an appropriate cleaning solution or airbrush cleaner.

Budding

Loose nozzle cap or air cap| Make sure nozzle cap is finger tight and/or

tighten air cap with wrench

---|---

Improper nozzle to body connection| Remove and reinsert nozzle. Try applying

thread sealer to the nozzle threads if there are scratches where the nozzle

meets the body.

Charked or damaged nozzle.| Replace nozzle.

Incorrectly heedle depth| Remove and reinsert needle to adjust It.

Skipping

Paint dried on needle tip/ nozzle blockage| Disassemble the airbrush and clean

the nozzle & needle thoroughly using an appropriate cleaning solution or

airbrush cleaner.

---|---

Paint too thick| Thin or strain paint to skim milk consistency.

Dirty airbrush| Deep cleaning the airbrush.

Cracked or damaged nozzle| Replace nozzle

Spattering

Dried paint on heedle tip/ Nozzle blockage| Disassemble the airbrush and clean

the nozzle & needle thoroughly using an appropriate cleaning solution or

airbrush cleaner.

---|---

Paint build up In needle cap| Clean needle with cotton swab dipped in

appropriate cleaner

Air pressure too low| Gradually increase the air pressure until you achieve

the desired spray pattern.

Paint too thick| Thin or strain paint to skim milk consistency.

Dirty airbrush| Deep clean the airbrush.

Gralny or Textured spray

Dried paint on needle tip/ Nozzle blockage| Disassemble the airbrush and clean

the nozzle & needle thoroughly using an appropriate cleaning solution or

airbrush cleaner.

---|---

Paint too thick| Thin or strain paint to skim milk consistency.

Air pressure too low| Gradually increase the air pressure until you achieve

the desired spray pattern.

Bad quality Paint| Use high-quality paints from reputable manufacturers for

better results.

Uneven surface| Sand the surface if necessary and apply a suitable primer or

base coat before airbrushing.

Spidering

| Paint is too thin or watery | Thin or strain paint to skim milk consistency. |

|---|---|

| Alr pressure too high | Adjust the pressure to a lower, more suitable level for |

your airbrushing needs.

Holding the airbrush too close or at an Incorrect angle| Maintain an

appropriate distance and angle for |the desired effect.

Paper bucking

Applying too much paint In one area| Apply light, even coats and allow each

layer to dry before adding another.

---|---

Paper too thin| Choose a heavier or thicker paper that is better suited for

airbrushing.

Too close to the surface| Maintain a suitable distance.

Repair

- Broken nozzle/ nozzle threads stuck

Use the small reamer to uncrew the broken part out from the airbrush.

Use the small reamer to uncrew the broken part out from the airbrush. - Bent needle repair

STP 1. Find a nickel coin or any similar object with a sharp edge that can be used to un-snag the tip of the bent needle. Ensure that the edge Is clean and free from any debris that could potentially cause further damage.

STP 1. Find a nickel coin or any similar object with a sharp edge that can be used to un-snag the tip of the bent needle. Ensure that the edge Is clean and free from any debris that could potentially cause further damage. STP 2. Place the bent needle on the flat surface, Using the flat part of the nickel, gently roll it along the length of the needle, applying light pressure. This rolling motion helps to identify any remaining bends in the needle.

STP 2. Place the bent needle on the flat surface, Using the flat part of the nickel, gently roll it along the length of the needle, applying light pressure. This rolling motion helps to identify any remaining bends in the needle. STP 3. Apply gentle pressure and gradually roll the nickel to straighten out the bend. Continue this process until the needle is uniformly straight.

STP 3. Apply gentle pressure and gradually roll the nickel to straighten out the bend. Continue this process until the needle is uniformly straight.

Read User Manual Online (PDF format)

Read User Manual Online (PDF format) >>