Get Packed BenchMATE Label Printer User Manual

- June 9, 2024

- Get Packed

Table of Contents

Get Packed BenchMATE Label Printer User Manual

LABEL SPECIFICATIONS

76mm core (manual machines)

35mm or 76mm core (electric machines)

Maximum 300mm roll diameter

Label Length

10mm – 650mm length for single labels

10mm – 220mm combined length for two labels

Height (width) 10mm – 230mm*

- Label height dependent on machine,

Left Edge Leading, Outside Wound

Commonly known as Roll Type 4

Left Edge Leading, Inside Wound

Commonly known as Roll Type 8

Please ensure your label backing liner is NOT perforated

Transparent label backing liner may benefit from a rewinder to avoid static

build up.

DESIGNING YOUR LABELS

No matter which labelling machine you use, it is important to make sure your labels will be suitable for the container, jar, can, bottle, tube or round object you want to apply labels to. Please read our guidelines below so you can design labels that will best fit your products.

Containers and Jars

Many containers have a ridge at the top and near the bottom.

When designing your labels, you will need to consider the accuracy of these ridges, which in our experience can vary by as much as 2.5mm.

The accuracy is determined by shrinkage in material, the manufacturing processes and age of the moulds.

For best practice, keep the top and the bottom of your label away from these

ridges by 3mm either side.

Cans

Cans have issues usually caused in transportation or in the manufacturing process.

We also advise that you design your labels to be 3mm away from both the top

and bottom of any ridge or change in the surface diameter.

Glass

Glass bottles are imperfect and even minor imperfections will cause visible issues in labels.

For most glass bottles, jars and containers, a full wrap around label is likely to have wrinkles, bubbles or will not meet up perfectly at the ends, unless the glass quality is exceptional.

We recommend a front and back label for all glass containers, but we are happy

to test your glass quality in-house if you want a full wrap around label.

General Recommendations

- When designing your labels, look at what your industry normally does. For example, wine bottles usually have front and back labels due to glass quality.

- Design for the worst possible conditions, such as a bad pallet of containers, to ensure you have the easiest labelling experience.

- If you are unsure about your container, don’t hesitate to ask for our advice. In our 30 years of manufacturing labelling machines we have plenty of tips and tricks up our sleeves that we’re happy to share.

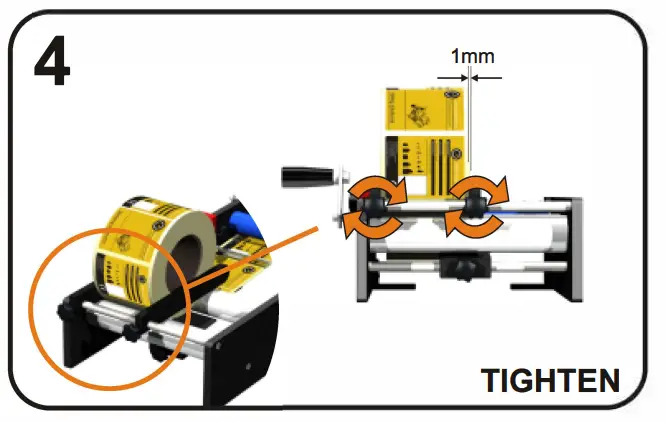

CUTTING YOUR ROLLERS

_ Remove Roller

Measure

Cut Roller

Replace Roller_

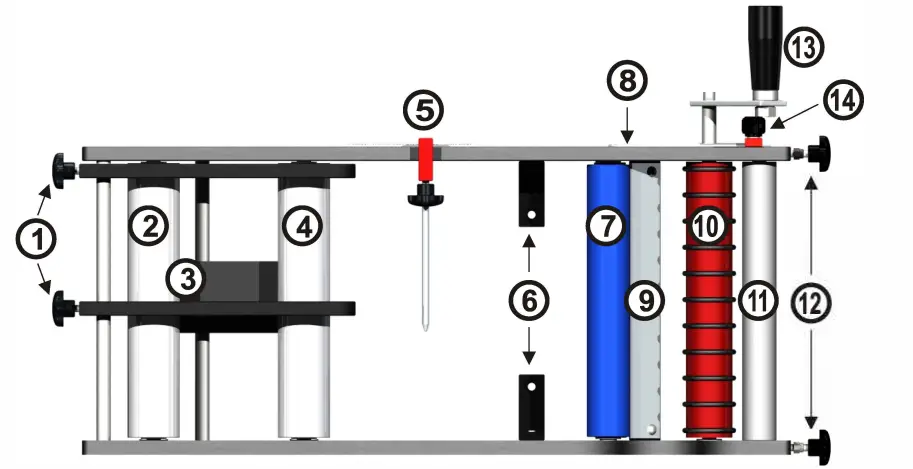

COMPONENTS OF THE BENCHMATE

PACKING LIST ITEMS:

Top View

| Guide Arm Thumbscrews | Indicator 2 – first label |

|---|---|

| Plastic Roller 1 | Peel Plate |

| Tensioner | Red Roller with O Rings |

| Plastic Roller 2 | Plastic Roller 3 |

| Indicator 1 – Second label | Thumbscrews with Locknuts |

| Clamp Points | Handle |

| Blue Rubber Roller | Indicator 2 Lock-of |

EXTRA COMPONENTS OF THE BENCHMATE

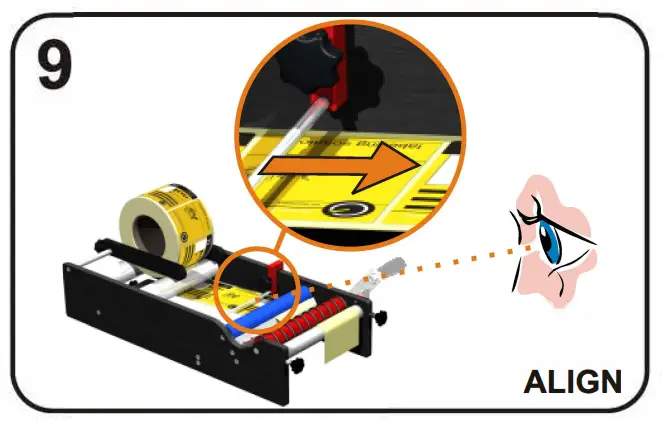

THREADING YOUR LABELS

MAINTENANCE

REPLACING ‘O’ RINGS

WEAR MAINTENANCE

029452-3566

sales@getpacked.com.au

www.getpacked.com.au

References

Read User Manual Online (PDF format)

Read User Manual Online (PDF format) >>