SVAB Quantum Tool Recognition User Manual

- June 6, 2024

- SVAB

Table of Contents

Quantum Tool Recognitio n

User manual

Introduction

General

Quantum Tool Recognition is a system for wireless tool recognition on

excavators. This is the only usage intended for this product. All other usages

of this machine, without written permission from SVAB, are strictly

prohibited.

This document gives instructions on how to do installation work on a Quantum

Tool Recognition system. SVAB reserves the right to change the contents of

this instruction at any time without further notice.

SVAB develops and produces its products in accordance with European

legislation and the machinery directive 2006/42/EG. The CE marking shows that

the system fulfills the directive of electromagnetic compatibility EMC, RoHS,

and radio directive RED.

This installation instruction shall be used in the technical file which will

be the base for

the final CE marking of the machine. Therefore, the checklist in this

instruction shall be thoroughly performed, completely filled out, and signed

by the responsible fitter. Save this instruction in the technical file.

The installation of the system referred to in this document is to be performed

by experienced personnel. If there are unclarities regarding the use,

installation, understanding of the system, or regarding this document –

disengage the installation work and contact the system provider for

information. By using common sense you can avoid accidents from happening

yourself

This instruction is protected by copyright and may not be reproduced,

distributed, or altered. Violation of the law may lead to prosecutions and

fines, imprisonment, or a duty to pay compensation to the creator/proprietor.

FCC and ISED

Changes or modifications to the equipment not expressly approved by the party

responsible for compliance could void the user’s authority to operate the

equipment.

This device complies with Part 15 of the FCC Rules. Operation is subject to

the following two conditions:

(1) this device may not cause harmful interference, and (2) this device must

accept any interference received, including interference that may cause

undesired operation.

To comply with FCC/IC RF exposure limits for general population/uncontrolled

exposure, the antenna(s) used for this transmitter must be installed to

provide a separation distance of at least 20 cm from any persons and must not

be co-located or operating in conjunction with any other antenna or

transmitter.

NOTE: This equipment has been tested and found to comply with the limits

for a Class B digital device, pursuant to Part 15 of the FCC Rules. These

limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates, uses,

and can radiate radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not

occur in a particular installation.

If this equipment does cause harmful interference to radio or television

reception, which can be determined by turning the equipment off and on, the

user is encouraged to try to correct the interference by one or more of the

following measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and receiver.

- Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

- Consult the dealer or an experienced radio/TV technician for help.

RSS standard

This equipment is exempt from the routine RF exposure evaluation requirement

of RSS-102. This equipment should be installed and operated with a minimum

distance of 20 cm between the antenna and the user or bystanders. This device

contains license-exempt transmitter(s)/receiver(s) that comply with

Innovation, Science, and Economic Development Canada’s license-exempt RSS(s).

Operation is subject to the following two conditions:

- This device may not cause interference.

- This device must accept any interference, including interference that may cause undesired operation of the device.

CAN ICES-3 (B)/NMB-3(B)

Support

Contact SVAB at: SVAB, Ulvsättersgatan 2SE-694 35 Hallsberg

Phone: +46 (0)582 152 30 (main) +46 (0)0582 152 33 (Support)

On our website www.svab.se you will find additional

information.

Approved areas of use

If you are unsure whether the function is allowed to control, always ask a

technician from your system provider.

Approved areas of use for Quantum ToolRec:

- Tool recognition on excavator

- Provide input signal to compatible systems

Quantum shall only be used for approved areas of use and functions as

mentioned above.

SVAB will not take part in injuries or accidents that occur due to

unauthorized use.

Environment

As part of our environmental commitment, we strive for our products to have an as little environmental impact as possible throughout the lifecycle. This means there are things to consider during the installation.

- All assembly/disassembly must be done according to national requirements and local regulations.

- Recycle waste according to national requirements and local regulations.

Technical Description

System overview

| Pos | Artikel | Benämning |

|---|---|---|

| 1 | P-0000963 | Quantum hub |

| 2 | P-0000966 | TRM |

| 3 | P-0001345 | Cable supply Quantum Hub |

| 4 | P-0001346 | Cable Quick coupler signal Quantum Hub |

| 5 | P-0000585 | Connecting cable Digging system |

| 6 | P-0000723 | M12 Connector male, straight 5 – pole |

| 7 | n/a | Quantum App (Google Play/App store) |

| 8a | 200586 | Jumper cable M8, 0,3 m |

| 8b | 149209 | Jumper cable M8, 1 m |

| 8c | 149207 | Jumper cable M8, 2 m |

| 9 | P-0001304 | Cover TRM |

Main parts

Quantum hub

The hub consists of the following main parts:

- CAN1 / 8-36 VDC

- I/O

- CAN2

- Diodes

- Nameplate

TRM (tool Recognition Module)

The TRM consists of the following main parts:

- Screw

- Cover

- Seal

- Battery

- Lower part

Technical data TRM

Dimensions

System

| | Unit| Remark

---|---|---|---

Min| Nom| Max

Mass| | 90| | g|

Material| | PC/PBT| | |

Operating temp| – 40| | + 70| C|

Storage temp| – 40| | + 85| C|

Voltage feed| 1.8| 3.6| 3.9| V|

Battery time| | | 5| år| Up to 5 years, depending on the degree of use

and environment

IP-rating| | IP67| | |

Bluetooth

| Description | Kommentar |

|---|---|

| Bluetooth | Bluetooth 4.1 |

| Frequency | From 2.4 GHz to 2.4835 GHz (ISM band) |

| Range | up tol 30 m |

Technical data HUB

System

| | Enhet| Kommentar

---|---|---|---

Min| Nom| Max

Vikt| | 180| | g|

Material| | PA6| | |

Driftstemp| – 20| | + 70| C|

Förvaringstemp| – 20| | + 85| C|

Spänningsmatn| 7.5| 12/24| 36| V|

CAN motstånd| | | | | Software selectable 120 Ω, 600 Ω, not terminated

IP-klassning| | IP50| | |

Bluetooth

| Description | Kommentar |

|---|---|

| Bluetooth | Bluetooth 4.1 |

| Frequency | From 2.4 GHz to 2.4835 GHz (ISM band) |

| Range | up tol 30 m |

Funktion

Tool recognition

Quantum Tool Recognition is a system for wireless tool recognition on

excavators. The system identifies which tool is connected to the excavator’s

attachment or to the tiltrotator’s attachment. Tool Recognition is based on

each tool being equipped with a compact and robust battery-powered device

(TRM) that communicates wirelessly with a controller in the cabin(Quantum

HUB).

The tiltrotator and/or machine quick coupler is connected to the system to

detect when a change of tools occurs. In cases where the machine is equipped

with a Quantum or MACS RT-based tiltrotator control system, the information is

shared when a tool change under the tiltrotator through the CAN bus. When

initiating a change, the system starts scanning for moving tools. The system

uses several smart conditions to identify the correct tools.

CAN-bus – interface towards external systems

The system hub can transmit the information to other control systems in the

excavator via the CAN bus. This way, these systems can adapt to each tool. An

example of a function is to automatically indicate the correct tool for the

machine’s GPS / 3D excavation system without the operator having to manually

enter it, or to automatically change settings in a Tiltrotator control system

based on the tool type.

Tracking of tools and machine

The system stores the user’s smartphone GPS position in the cloud and connects

it to the tool and machine shown on a map in the app, provided that the user

has:

- Downloaded the Quantum app to his/her smartphone

- Approved that the app has access to location information

- Bluetooth connection with HUB and/or TRM devices

- Internet Access

The information about the position of a tool or machine is also shared by

other users who have a Bluetooth connection with any Quantum HUB or TRM

device. It is enough for someone who has the Quantum app installed on their

smartphone to pass a HUB or TRM and get connected via Bluetooth to update the

location in the cloud. The information is sent anonymously and is displayed

only for those users who registered the current machine or device in their

app.

Operating time and service intervals

Quantum Tool Recognition together with the Quantum app also keeps track of the

machine and tool’s operating time. The machine’s operating time is measured in

time as the hub has been powered, the tool’s operating time is measured in

time as the TRM unit has been connected to the HUB and at the same time is in

motion.

In the app, you can define multiple service intervals for both the machine and

the tool, the app will then notify you via notifications to it when it’s time

for service.

Start using Quantum ToolRec

1. Quantum starts when the electronics of the machine are activated by the ignition.

Start the Quantum hub

Power up the machine

The Quantum hub will start and the diodes will start to flash. The LEDs are

called (from the left): LED 1, LED 2, LED 3, and LED 4.

LED 1 (Heartbeat), LED 2(TOOLREC-searching),

LED 3 (quick coupler), LED 4 (TOOLREC-status)

2. Check that LED 1 is flashing green. As long as the hub is running, the led will flash.

3. LED 2 flashes blue when searching for a tool. If LED 2 flashes green, it searches for a tilt rotator. If LED 2 flashes blue and green respectively, it searches for both tilt rotator and tools.

4. Check the lower coupler function by activating it. LED 3 lights up with a green steady light.

5. Check the upper coupler function by activating it. LED 3 lights up with a

red steady light. If both couplers are open, LED 4 lights up with a yellow

light.

6. When a tiltrotator has been identified, LED 4 lights up with a green

steady light. When a tool has been identified, LED 4 lights up with a blue

steady light

7. LED 4 lights up with a steady white light when both the tilt rotator and a tool have been identified.

Quantum App

Registration of users, machines, and tools

Register a user

Download the SVAB Quantum app from App Store or Google Play.

-

Start by creating a new user.

-

Enter user information and password. Click ”Next”.

You need to accept the license agreement in order to get to the next step in the registration. -

Wait for a confirmation mail and follow the instructions in the mail.

-

Your registration will be confirmed

Add a pre-registered machine

-

Go to ”Machines” to register a new machine.

Please note that the machine must be running in order for the system to function -

Press the + sign to scan for and register machines.

If your machine was configured in a workshop, your machine will show up as a machine nearby. -

Click on the machine to open the profile.

-

To edit the given information, click on ”Edit”. From here, you can change the name and change or add a picture.

-

Press ”Save” when you are done. The machine is added to your list.

Register a new machine

If the machine hasn’t been registered before, it needs to register from start.

-

Go to ”Machines” to register a new machine

Please note that the machine must be running in order for the system to function -

Press the + – sign to scan for and register machines

-

The machine will show up as an unknown machine. Click on the machine to register. Name the machine and add a picture if desired.

-

Press ”Save” when you are done. The machine is added to your list.

Add a pre-registered tool

-

Go to ” Work tools” to register a tool.

Please note that the machine must be running in order for the system to function

If your machine was configured in a work shop, one or several tools will be available in the app. -

Press the + – sign to scan and register for a tool.

-

Click on the tool to be registered.

-

To edit given information, press ”Edit”. From here, you can change your name or add or change a picture if desired.

-

Press ”Save” when you are done. The tool will be added to your list.

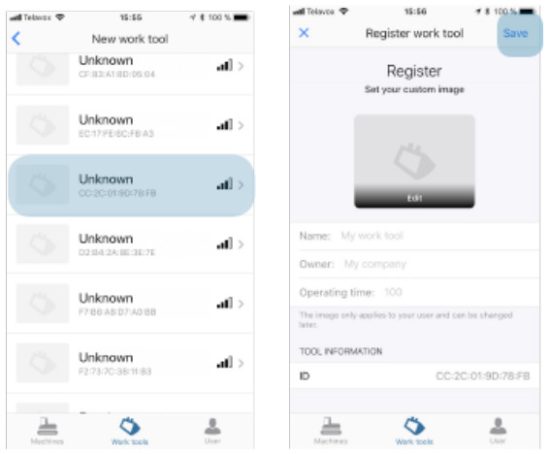

Register a new tool

If the tool hasn’t been registered before, it needs to register from the

start.

- Go to ” Work tools” to register a tool.

- Press the + – sign to scan and register for a tool.

- The tool will show up as ”Unknown”, with a MAC address. Compare the numbers on the installed TRM module.

- Select the tool to be registered. Name the tool and add a picture if desired.

- Press ”Save” when you are done. The tool will be added to your list.

Tiltrotator TRM

The tilt rotator TRM is predefined by the factory and will show up on the

screen

Connect machines and tools

Connect a machine

You can have several machines added to your list. When you start your machine,

Quantum hub will start up and scan for machines and tools.

You can see if your machine is available by looking at the strength of the

signal, to the right.

Connect a tool

- Start the machine.

- Activate the quick coupler and lock to a tool.

- Quantum Toolrec will now start to scan for and connect to the tool in the app.

- You can verify that the tool is connected to your machine under ”Working tools”.

Change tools

- Activate the quick coupler and release the tool.

- Lock on to the new tool.

- Quantum ToolRec will start a new scan and connects to the tool.

Under ”Map” the position of each machine and tool is shown.

Service

Under ”Service” or for your tool. These will end up under ”Notifications” when it’s time to perform a measurement. You can also see the operating time for your machine or tool.

- Press the +-sign to create an activity.

- Name the activity and the hours for the interval. Press ”Save”.

Maintenance

Maintenance schedule

| Description | Maintenance | Interval | Remark |

|---|---|---|---|

| TRM | REplace battery | 5 yrs | |

| Replace cover | When necessary | ||

| Replace TRM | When necessary |

Maintenance instructions

Preparations before maintenance

- Make sure that the machine is turned off and the excavator boom is lowered.

- Clean the area around the TRM to avoid dirt from entering the module when dismounting.

Replace battery

-

Remove two screws holding the cover.

-

Use a screwdriver to separate the cover from the lower part.

-

Remove the seal between the cover and the lower part.

-

Replace the battery in the unit.

Make sure to only use original batteries from SVAB. The unit will not work with ordinary 1.5 V batteries. -

Install a new seal [1] between the cover and the lower part. Make sure that the seal fits the groove properly.

-

Put the cover back.

Make sure to turn the cover in the correct position so the notch [2] fits the battery. -

Reinstall the 2 screws. Tightening torque 0.8 Nm.

The TRM module should be mounted on the tool at room temperature for results. The temperature may not go under – 10 gra C.

The module is delivered with the battery, sealing, and screws on the side.

-

Remove the old TRM from the tool

-

Clean the surface before mounting the new module.

-

Remove the cover on the module and install the battery.

Install the seal. Make sure that the seal fits the groove properly.

Make sure that the seal fits the groove properly. -

Put the cover back.

Make sure to turn the cover in the correct position so the notch [2] fits the battery. -

Note the MAC address on the module. This number will show up in the app later on. You will find the label on the side of the module. Example of a MAC- address: C6:6D:D5:27:4F: B5.

Recommended spare parts

TRM

| Pos | Part | Description |

|---|---|---|

| 1 | P-0001366 | TRM |

| 2 | P-0000967 | Battery kit |

Recycling

Replaced parts are recycled according to local laws and regulations or are returned to SVAB.

Read User Manual Online (PDF format)

Read User Manual Online (PDF format) >>