UNOX LineMicro Shelves Electric Convention Oven Instruction Manual

- June 16, 2024

- UNOX

Table of Contents

- Explanation of pictograms

- Introduction

- INSTRUCTIONS FOR THE USER

- Safety regulations

- Appliance instructions

- Manual Control

- Setting the cooking temperature

- INSTRUCTIONS FOR THE INSTALLER

- First operations and positioning

- Installing the appliance

- Electrical connections

- Oven cavity smoke exhaust

- Certification

- Read User Manual Online (PDF format)

- Download This Manual (PDF format)

UNOX LineMicro Shelves Electric Convention Oven Instruction Manual

Explanation of pictograms

Danger!

Situation presenting immediate danger, or a hazardous situation which could

cause injury or death.

Danger: fire hazard!

Danger: electric shock!

Read operator’s manual

Danger: risk of burns

Tips and useful information

Protective earth symbol

Equipotential symbol

Consult other chapter

Introduction

Dear Customer,

We would like to congratulate and thank you for choosing to purchase an oven

in the Line Micro™ range; we hope this is just the beginning of a fruitful and

long-lasting partnership.

The following information and recommendations regard correct appliance installation, use and maintenance in order to protect you from harm and offer best appliance performance.

INSTRUCTIONS FOR THE USER

Caution

Read this instruction manual with attention as it contains important

guidelines on your safety and on using the appliance. Store this booklet with

care so that it is available to other operators.

Safety regulations

All installation procedures and electrical connections must be performed by

qualified personnel according to the regulations in force.

General safety regulations

The appliance must be used solely for what it was designed for.

The oven was designed to baking foods as specified below. All other uses are

inappropriate.

The oven’s work temperature range is 0 – 260 °C (0 – 500 °F).

The appliance can be used for the following:

- cooking Pastry and Bread goods, whether fresh or frozen;

- bringing chilled and frozen food back to normal temperature

If you want to open the oven door while it is running normally while

maintaining its integrity,

we recommend that you open the door completely so that the heat is dispersed

into the environment and does not damage the side columns.

Space pans at least 20 mm apart to allow air circulation when placing food

into the oven cavity.

Do not salt food inside the oven cavity.

Do not cook foods containing easily flammable substances (e.g. alcohol-based

foods).

Substances having a low point of inflammability can auto-ignite – possible

fire and explosion inside the oven cavity that can cause the door to abruptly

open, even violently.

Cleaning and scale removing fluids, as well as their relative accessories, can

only be used for the purposes described in this manual.

All other uses do not comply and is thus dangerous.

Replace the glass windows of the doors immediately if they are damaged.

Danger: abrupt breakage.

Personnel must attend training and safety courses on a regular basis to avoid

accidents or damage to the appliance.

Safety regulations

Use: safety regulations

This appliance can be used by children aged from 8 years and above and persons

with reduced physical, sensory or mental capabilities or lack of experience

and knowledge if they have been given supervision or instruction concerning

use of the appliance in a safe way and understand the hazard involved.

Children shall not play with the appliance. Cleaning and user maintenance

shall not be made by children without supervision.

Children must be supervised to ensure they do not play with the appliance.

When using the oven for the first time, make sure that the instruction booklet, plastic bags or other objects are inside the oven cavity.

Make sure that all hanging frames and tray-holder trolley inside the oven cavity are locked in place as called for by the regulations – containers with hot fluids may fall or slip out of the oven cavity – danger: burns !

Make sure that the oven cavity is free of any cleaning fluid residue before cooking. Remove any cleaning fluid residue using a damp cleaning cloth and using suitable protection equipment for hands, mouth and eyes. Rinse thoroughly – Danger: Corrosion!

The control panels can be activated only by fingertip; any other object may cause damage and/or malfunctions thus invalidating the guarantee.

Operate the appliance at a room temperature between +5°C and +35°C.

External components may exceed 60 °C: Touch only the appliance control

components. Risk of burns!

When the trays contain fluids or are filled when cooking, do not use racks

that do not allow you to see inside the tray – risk of burn!

When removing trays containing hot fluids be careful of any spills.

Pay close attention when handling trays of food during and after cooking: they may be extremely hot and cause burns.

Wear protective thermal garments when touching accessories and other objects inside the heated oven cavity – risk of burns!

Always open the door slowly and with caution: risk of burns due to expulsion of extremely hot steam.

Never place objects that are highly flammable or easily ignite near the oven – risk of fire!

Care, inspection and cleaning

Clean the oven cavity daily to maintain proper levels of hygiene and to keep

the steel inside the oven cavity from getting ruined.

Caution!

Failure to clean the appliance properly and with adequate frequency may lead

to ignition of food or fat residue inside the oven cavity – risk if fire!

Clean the oven each day to avoid corrosion inside the oven cavity.

Do not clean the appliance using high pressure cleaners with hot water sprays

or high pressure steam jets. Use cleaners that are recommended by the

manufacturer of the appliance.

Cleaners produced by other manufacturers may cause damage and, therefore,

forfeiture of

the guarantee. Do not use abrasives or corrosive detergents.

Cleaning the oven cavity seal daily with a non-abrasive cleaner lengthens the

life of the appliance.

Do not use acid-based products and/or abrasive tools and or products.

Do not use a pressurized water to clean outside surfaces.

Use damp cloths and specific products to clean the steel.

Do not use acid-based products and/or ammonium.

Installation, inspection, maintenance and repairs

Danger: high voltage!

Installation, inspection, maintenance and repairs must be performed by

qualified and properly trained personnel. Disconnect the electricity supply to

the appliance before performing these actions.

If the appliance is seated on a wheeled support, make sure that the allowed movement does not cause damage to electrical cables, water hoses, drainage pipes or else. Do not place heat sources next to the appliance.

Make sure that all electrical cables and discharge tubes are properly disconnected when moving the appliance. If the appliance is moved to its original position, make sure that the braking mechanism is engaged and that electrical cables and drainage pipes are properly connected.

It is best to have an authorized customer assistance service perform maintenance on the appliance at least once a year to ensure top working conditions.

Appliance instructions

Do not place heat source (e.g. grilles, fryers, etc.) near the oven.

The heating system and the fan automatically switch off when opening the oven

cavity door (only for the “Domenica” model). The built-in fan disengage

mechanism is triggered. The fan continues to spin briefly.

If the appliance was left running for more than 15 minutes without selecting an operating mode, stand-by is automatically engaged for energy savings. To exit stand-by mode simply touch the START/STOP button for at least 3 seconds.

If the oven undergoes lengthy stand-by (e.g. during the night), leave the oven cavity door slightly ajar.

If the oven is inactive for lengthy periods (e.g. non-business days), take the appliance power off line.

The oven must not be disposed of as domestic waste or placed in the used appliance bins of municipal waste collection centres when the oven has reached its end of life. We are glad to help you properly dispose of the appliance.

Guarantee

Installation of the UNOX product must be performed by an Authorized UNOX

Assistance Service. The installation date and appliance model must be

documented by the end purchaser, by means of written confirmation or an

installation invoice issued by the dealer or the Authorised UNOX Customer

Assistance Service, otherwise this guarantee will not be valid;

The UNOX guarantee covers all malfunctions objectively linked to production defects. The guarantee excludes damage due to transport, poor product storage or maintenance or incorrect product use. Also excluded is damage due to installation not conform to the technical specifications provided by Unox and linked to the environment of use, such as, for example, unclean and aggressive water supply, low quality gas supply, or electrical supply failing to respect nominal voltage and power ratings. The guarantee also excludes any damage due to power surges or tampering by unauthorized or incompetent persons. The guarantee is also invalidated for damage to the appliance by lime scale deposits. In addition, the guarantee does not cover consumables, such as: seals, light bulbs, glass panels, decorative parts and parts consumed during use.

Guarantee rights will also be invalidated in the event of damage arising as a result of incorrect installation, or installation which has not been carried out by an Authorised Customer Assistance Service.

Manual Control

Setting the cooking duration

The cooking duration can be set by using the dial (dial on the left): the time

can be set anywhere from 0 to 60 minutes.

Turning the dial clockwise sets cooking duration; while turning it counter-

clockwise (manual position) sets the oven to continuous mode.

Turning the dial starts the oven and activates fan rotation and any interior

lights.

The dial stops on the zero and the oven switches off when the cooking cycle is

over.

The oven is off only when the timer dial rests precisely on the zero “0” mark. Wait 5 minutes before leaving the appliance unattended to ensure proper functioning.

Setting the cooking temperature

The temperature inside the oven cavity can be set by using the temperature

dial (dial to the right):

the temperature can be set anywhere between 0 to 260 °C (0-500 °F).

when on, the green temperature indicator light shows that the resistor is

activated, which switches off as soon as target temperature has been reached.

INSTRUCTIONS FOR THE INSTALLER

Safety regulations:

All installation, assembly and maintenance must be performed by qualified

personnel according to the regulations in force. The assigned technical

personnel must be fully informed and apply the safety regulations for repaired

products, as well as safety measures on the workplace. The guarantee will be

forfeit if the appliance is installed by qualified technicians not authorized

by UNOX. In consideration of the above, UNOX has no liability for any errors

made during the stated operations, or for any errors due to misinterpretation

or incorrect application of the regulations or of this manual.

Caution!

Installation, assistance, maintenance or cleaning that are performed

incorrectly, as well as any modifications to the appliances may cause damage,

harm or fatal accidents. Carefully read the installation instructions before

installing the appliance.

First operations and positioning

Place of installation

Before positioning the oven, measure the space and exact position required by

the electrical connections, plumbing and smoke exhaust according to the

drawings in the attached folder “Technical Specifications”.

Caution!

Do not install the appliance near flammable material.

Walls, partitions, kitchen furniture, decorative mouldings, etc. must be made

on flame-resistant material if located near the oven.

Otherwise, they must be coated with thermal flame-resistant insulation, and

maximum caution must be taken to respect the fire prevention regulations.

Removing the protective film

Remove the protective film from the outside walls of the appliance carefully

and make sure that no glue remains attached to the oven. Use a special solvent

to remove any adhesive residue.

Attaching the feet

The feet contained in the bag inside the packaging are necessary to ensure air

flow to cool the electronic components and outer walls of the oven. Therefore,

they must be properly mounted to the appliance. Insert the feet in the

positions shown in the figure. Caution! Do not use the oven if the feet are

not mounted because this may lead to electronic component overheating and

irreversible damage..

Installing the appliance

Warning

Position the appliance respecting the safety regulations indicated hereafter.

Position the appliance so that the rear and side panels are easy to access for

all electrical connections and to allow its maintenance.

The appliance is not designed for recessed installation or incorporation with

other equipment; therefore, never stack when using more than a single oven.

Position the appliance 10 cm from the rear wall and the oven exhaust.

With particular reference to ovens, all models must be placed onto a base such

as a proover, tray rack or flame-resistant table.

Do not install the ovens when set on the floor.

Make sure that any walls, partitions, kitchen furniture, decorated mouldings,

etc. near the oven are not flammable.

Otherwise, they must be coated with thermal flame-resistant insulation, and

maximum caution must be taken to respect the fire prevention regulations.

If the oven is near fryers or other sources of hot fluid splashes, keep at a side distance of at least 45 cm and a rear distance of at least 70 cm from the oven

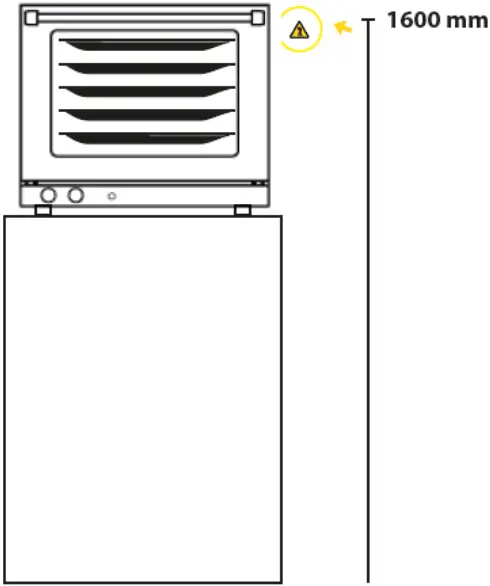

Due to safety reasons, table-top appliances must be positioned on sub-

structures or cabinets I produced by the appliance manufacturer. Maximum work

height of the topmost oven shelf is 1600 mm.

Safety stickers “max. height of the last rack for trays containing

liquids” are inside the oven. After installing the oven, apply the sticker at

a height 1600 mm. (see example)

Electrical connections

Warning

Electrical connections to the power main must be performed according to the

regulations in force. The appliance must be positioned so that the plug that

fits into the mains socket is easy to reach (for appliances with Schuko plug).

The isolating device must be connected upstream from the appliance connections

to the

power mains, in compliance with local regulations in force.

We recommend using a safety switch for electrical faults.

The power supply voltage must not deviate from the nominal voltage value

specified on the appliance rating plate when the appliance is operating.

Info Caution!

Electrical connections must be made by technicians registered in the

professional organisations called for by the law in order to practice their

profession in compliance with the regulations of the country of installation.

The assigned technical personnel must be fully informed and apply the safety

regulations for repaired products, as well as safety measures on the

workplace. In consideration of the above, UNOX has no liability for any errors

made during the stated operations, or for any errors due to misinterpretation

or incorrect application of the regulations.

Caution!

Respect the cable color code. An incorrect connection may lead to electric

jolts. An incorrect connection may damage the appliance.

Wire colour code:

Yellow/green = ground wire

Blue = neutral wire

Brown, grey or black = phase L1,L2, L3

Before connecting the oven to the power mains, compare the electrical system

specifications with those requested by the appliance, listed on its ratings

plate.

If voltage and phases are different, make sure to wire the appliance correctly

by following the indications on the sheets attached. Check that there is no

electric dispersion between phase and ground. Check the electrical continuity

between the outer casing and the system ground cable. Use a digital multimeter

for these operations.

Caution!

Make sure that all electrical connections are tightly secured before

connecting the device to the power mains.

a- Connection to the power mains must be done following the regulations

in force. Operate the appliance at a room temperature between +5°C and +35°C.

Make sure that voltage and frequency values correspond to those indicated on

the ratings plate on the oven before connecting it to the power mains.

The appliance must be positioned in such a way as to allow easy access to the

power plug. As regards for ovens equipped with plug-free power cord (XF040,

XF043 and similar), install a single-poles itch between the appliance and the

power mains that can be accessed after installation; the switch contacts must

have a 3 mm minimum gap and be of appropriate load capacity. We recommend

using a differential magneto-thermal switch. Check that the power supply

voltage does not deviate from the nominal voltage value specified on the

appliance rating plate by more than + 10%. The safety thermostat protection

must be tightly secured so that it cannot be removed without the aide of a

tool.

b- The appliance must be connected to the mains ground line.

In addition, the appliance must be included within an equipotential system,

whose efficacy must be appropriately checked according to the regulations in

force. This connection must be performed between different appliances with the

terminal marked with the symbol:

The appliance must be included within an equipotential system, whose efficacy must be appropriately checked according to the regulations in force. Equipotential connection consists in connecting the oven electrically with other electrical appliances in order to bring the different electrical ground lines to the same electric potential. The equipotential connection symbolism placed near the terminal to use for the equipotential connection. The equipotential wire must have a I minimum cross-section of 10 mm2 and be yellow-green.

- Ovens equipped with Schake plug (230V single-phase): simply insert the plug into the power socket (the socket must fit the power plug provided)

- Ovens equipped with power cord (400V, 3-phase + Neutral): these ovens have a 5-wire power cord: it is necessary to connect the appropriate 5-pole, 3-phase plug of adequate load capacity or connect the cord directly to an electric board.

The power supply cable may be replaced for ovens equipped with a 5-pole cable

in order to adapt the oven to the type of electrical current supplied. Follow

the procedures below to replace the power supply cable:

-

Open the terminal board cover by prying open with a suitable screwdriver from the two side flaps (1)

-

Undo the wire fastening screws (2)

-

Unscrew the cable clamp screw (3)

-

Remove the cable supplied

-

Connect the wires of the cable preferred by following the selected wiring diagram; make sure to tightly secure the terminal screws

-

Secure the cable using the cable clamp Close the terminal board cover again

Oven cavity smoke exhaust

WARNING:

Follow the wiring diagram when connecting the cable to the terminals:

insert the copper jumper and the power cable along with the screws, in the

screw down direction, so that both the jumper and the cable are tightly

secured when fastening the screws. Incorrect wiring may cause terminal board

overheating and melting.

Oven cavity smoke exhaust

A ventilation flue connected to the oven cavity is located on the rear portion

of the oven; hot smoke and steam are released during the cooking cycle (smoke

temperature and humidity depend on the oven operating parameters and on the

type and quantity of product placed inside the oven). The smoke that is

released from the flue can be expelled into the open atmosphere or condensed.

Disposal at end of life

According to Art. 3 of the Decretory Legislative n.49 of the Italian

Legislation of the 2014 “Implementation of the WEEE Directive on Waste

Electrical and Electronic Equipment 2012/19/EU”.

The WEEE symbol of a crossed out wheelie bin with a black line under it specifies that the product has been placed on the market after the 13th August 2005 and that at the end of its life it must not be disposed of together with other refuse but must be disposed of separately.

All the equipment has been made with recyclable metal materials (stainless

steel, iron, aluminium, zinc plate, copper, etc.) that as a percentage make up

more than 90% of the weight.

The equipment must be made ready for disposal by removing the power cable and

closing the door or any cavities (where present).

Attention must be paid to the management of this product at the end of its

life, reducing any negative impact on the environment and improving the

efficiency of resources, applying the principles of “who pollutes pays’,

prevention, preparation for re-use, recycling and recovery.

An lllegal or non-correct disposal of the product will lead to sanctions being

applied as per current legislation.

Information on disposal in Italy

In Italy all WEEE equipment must be delivered:

- to Collection Centres (also named “eco-islands” or “eco-platforms”)

- to the dealers from which new equipment has been purchased, who is bound to collect the old equipment free-of-charge (“one in one out” collection);

Information on disposal in European Union countries

The EU Directives on WEEE equipment has been implemented in different ways by

different countries, therefore in order to dispose of this equipment correctly

we suggest that you contact your local authority or your dealer in order to

ask the correct method of disposal.

Certification

Manufacturer: UNOX S.p.A.

Address: Via Majorant, 22 – 35010 Cadoneghe, Padua, Italy Declares, under

its own responsibility, that the product Line Micro™

complies with Machinery Directive 2006/42/EC in compliance with the following standards:

- EN 60335-1:2012 + A11:2014 + A13:2017 + A1:2019 + A14:2019 + A2:2019 + A15:2021

- EN 60335-2-42:2003 + A1:2008 + A11:2012

- EN62233:2008

complies with EM Compatibility Directive 2014/30/UE and is built in compliance with the following standards:

- EN 55014-1:2017 + A11:2020

- EN 55014-2:1997 + A1:2001 + A2:2008

- EN 61000-3-2:2014

- EN 61000-3-2:2014

- EN 61000-3-11: 2000

- EN 61000-3-12: 2011

- EN 61000-6-2: 2005

- EN 61000-6-3: 2007 + A1:2011

XAF series ovens are compliant the following standards: uL197 CSA C22.2

No. 109 NSF/ANSI 4-2009

Read User Manual Online (PDF format)

Read User Manual Online (PDF format) >>