CDM Custom Door and Mirror Installation Guide

- June 5, 2024

- CDM

Table of Contents

CDM Custom Door and Mirror

OWNER MANUAL + INSTALLATION GUIDE

DEAR CDM CUSTOMER

Welcome to the CDM family! If this is not your first CDM product— welcome

back! We are proud to manufacture quality products in our home state of New

York for over 60 years. It is our goal that you are completely satisfied with

your purchase and that your CDM door performs to your reasonable expectations

for its lifetime. We have over 1 million CDM doors installed to this day and

the list of happy customers continues to grow. If for any reason you are not

completely satisfied, please contact us and let us know what we can do to help.

HAPPY AND WANT TO LET PEOPLE KNOW?

Please take a moment of your time and write a review of your experience. You

can login to the retailer’s website where you purchased the door, Google or go

to our website. Small family business manufacturers like CDM rely on strong

reviews and happy customers that spread the news about our wonderful products.

If for any reason you feel like you can’t give us a positive review, please

contact us at

sales@customdoorandmirror.com and let

us know what we can do to get you added to the list of happy and completely

satisfied CDM customers.

CARE AND MAINTENANCE INSTRUCTIONS

Before installation, doors should always be stored flat and on a level surface.

Doors should never be leaning against a wall or not properly supported, as

this may cause warpage, especially if doors are acclimating to a new interior

climate/humidity level. Door hinges and rollers should be lubricated every 6

months. We recommend a dry lubricant. Look for a Teflon or Dry lubricant. Spray

each hinge sparingly from both front and back and wipe off excess. A little

will go a long way. The doors will work very smoothly for their lifetime if

they are properly lubricated.

MIRROR MAINTENANCE

DO NOT USE AN AMMONIA BASED CLEANING PRODUCT. These will shorten the life of

the mirror by creating a dark edge or dark spots over time. The most important

thing to remember is to use an alcohol or water based cleaner. There are many

fine aerosol and liquid products at your local retailer.

LIFETIME HARDWARE WARRANTY

The Custom Door and Mirror (CDM) Warranty is a statement of confidence to our

customers to the reliability of CDM’s products, which are designed and

manufactured to the highest standards in quality, appearance and durability.

This warranty reflects a tradition of excellence and a commitment to superior

manufacturing and innovative design dedicated to you, our customer. This

warranty is our pledge to you that we will proudly stand behind our products.

CDM warrants our hardware for its lifetime to be free from defects in

materials and craftsmanship. This Lifetime Warranty applies to the original

owner/purchaser of the CDM product and is not transferable.This includes

hardware, hinges, rollers, guides and handles for the natural life of the

product. CDM reserves the right to repair, replace, or refund the original

purchase price, at its option, any hardware found to be defective. Proof of

purchase required.

ADDITIONAL WARRANTY

In addition, CDM warrants the remaining components to be free from defects in

materials and workmanship upon inspection, and proof of purchase, will repair,

replace, or refund the original purchase price, at its option, if any

components are deemed to be defective by a representative of CDM. This

includes door panels, tracks, trim, etc. There are no additional warranties,

expressed or implied, which extend beyond the description on the face hereof,

including the implied warranty of fitness and the implied warranty of

merchantability.

WHAT THIS WARRANTY DOES NOT COVER

Broken mirrors, shipping damage, negligence, improper handling/storage, or any

costs associated with repairing or replacing a product found to be defective.

This warranty is applicable to original owner and only when the products

covered by it have been installed in accordance with the recommended written

installation instructions supplied by CDM and with established building

practices. In addition, the warranty is applicable only if the CDM products

have been accorded treatment which is considered good practice in the building

industry regarding storage and maintenance and have been subjected only to

normal use. Instances that involve improper installation, accident, natural

disaster, corrosive air, outdoor use, or product that has been altered will

not be covered. Because CDM cannot control the way its products are handled

after leaving its premises, this warranty does not apply to the finish or other

damage occurring during shipment. Some states do not allow the exclusion or

limitation of incidental or consequential damages, so the above limitation or

exclusion may not apply to you. This warranty bestows certain legal rights,

and you may also have other rights which vary from state to state.

SLIDING DOOR | INSTALLATION GUIDE

HARDWARE INCLUDED

-

WOOD BLOCK & METAL TRACK

-

PIVOT BLOCK

-

OAK SADDLE

-

METAL FLOOR PLATE

-

ROLLER BRACKET

-

SPRING

-

TOP PIVOT PIN

-

TOP PIVOT BRACKET

-

ADJUSTING BOLT

-

BOTTOM PIVOT BRACKET

-

HANDLE

-

2 – PLASTIC DOOR ALIGNERS

Only used when installing 2 pairs of bi-fold doors in the same opening -

2 – 2” WOOD SCREWS

-

24 – 5/8” #8 SCREWS

TOOLS REQUIRED

STEP 1

DETERMINE YOUR PIVOT & PREP THE TRACK

Slide and loosely secure plastic PIVOT BLOCK onto METAL TRACK Ensure that the

hole in the Pivot Block goes in the track closer to the edge and at the side

which you prefer your doors to open toward. The Flat surface of the METAL

TRACK is the front and it faces to the room. The PIVOT BLOCK should be 1” from

the edge of the track and loosely tighten the hex screw for now. For 4 door

openings you will need to repeat this process on the opposite end of the track

too. STEP 2

MOUNT UPPER TRACK

Attach WOOD BLOCK straight up to header of closet opening using 2 – 2” black

WOOD SCREWS M Block should sit 1/4” back from the front edge of the closet

door opening. With the flat side of the track facing the room push the METAL

TRACK over the WOOD BLOCK for snug fit. Cut aluminum track with a hacksaw if

necessary. Make sure that pivot block is positioned on the side you want the

door to open towards. Loosely fasten track to the block using two #8 SCREWS N

through the two holes on the inside of the track.

STEP 3

MOUNT FLOOR HARDWARE

Place OAK SADDLE C on the floor, 1/4” back from closet opening front edge to

align with METAL TRACK above. Pre-drilled holes in OAK SADDLE go on the same

side as the plastic PIVOT BLOCK. The door opens to the left, and holes go on

the left. The door opens to the right, holes go on the right. Don’t fasten the

SADDLE to the floor until the end of the installation. Lay METAL FLOOR PLATE D

over holes drilled in OAK SADDLE (slotted holes in plate face inside closet

opening). Fasten plate to saddle using 2 – #8 screws through slots in the

metal floor plate. Do not tighten them down yet completely. We may need to

adjust left or right STEP 4

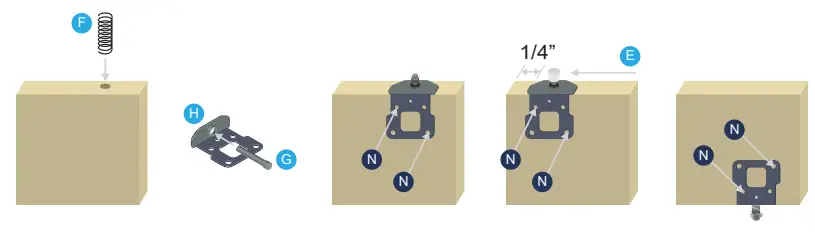

MOUNT DOOR HARDWARE

Next open your door & lay it face down. Drop SPRING F into hole on top of

the door; door opening to left use hole in top left & vice versa for door

opening to the right. Slide rounded end of TOP PIVOT PIN G up through TOP

PIVOT BRACKET H Mount this assembly over spring hole as shown. Fasten assembly

to back of door using two #8 SCREWS & test for correct installation by pushing

the PIVOT PIN G into door. Pin should now be spring-loaded. Fasten ROLLER

BRACKET E at top of door 1/4” from edge opposite of the pivot bracket using 2

– #8 SCREWS. Screw ADJUSTING BOLT into BOTTOM PIVOT BRACKET all the way up so

the door would sit as low as possible. Insert this assembly into hole at

bottom of door on the same side as TOP PIVOT BRACKET .Fasten BRACKET to

bottom back of door using 2 – #8 SCREWS  STEP 5

STEP 5

INSTALL DOOR

Fold doors together & stand upright. Lift at an angle to fit PIVOT PIN into

groove/hole in PIVOT BLOCK & ROLLER into track (1). You may hear the spring-

loaded pin “pop” into the hole. Lift to fit bottom ADJUSTING BOLT into cup on

METAL FLOOR PLATE (2). Sometimes it helps to have a 2nd person down low to

help find the cup. Make sure that the roller stays in the top track. Close

door slowly, making sure that there is at least 3/16” clearance between edge

of door & wall. If not adjust PIVOT BLOCK and/or METAL FLOOR PLATE left or

right accordingly.  STEP 6

STEP 6

ADJUST

To adjust HEIGHT alignment, turn bottom ADJUSTING BOLT to desired height. Use

5/16” wrench to adjust screw. Lock height adjustment by screwing one #8 SCREW

into smallest hole at back of BOTTOM PIVOT BRACKET. Now you can fasten the

saddle permanently to the floor. For wood floors we recommend 10d finish

nails, first pre-drill holes using 1/8” bit to prevent wood from splitting.

Cement floors require construction adhesive. To adjust WIDTH alignment, fold

and hold doors firmly in place and loosen hex head screws on PIVOT BLOCK and

METAL FLOOR PLATE. Position doors side to side, plumb and level, for best fit

and re-tighten PIVOT BLOCK and METAL FLOOR PLATE.  STEP 7

STEP 7

TIGHTEN, CLEAN & ENJOY

Place wrap-around Handle K approx. 39” from bottom of pivot panel. On a door

that opens to the LEFT, the pivot panel is the one on the LEFT. For doors that

open to the RIGHT, the pivot panel is the one on the RIGHT. Fasten it to back

of door using 1 – #8 SCREW. Now go back and make sure everything you’ve left

loose for the adjustments is tightened down. Aligners for 4-door units –

Install 2 sets of DOOR-TO-DOOR ALIGNERS L on the back of each meeting panel.

One set about a ½” up from the bottom and one set about 36” from the bottom.

These will keep your doors nice and flush with each other.

631.414.7725 | www.customdoorandmirror.com | sales@customdoorandmirror.com

References

- Custom Closet Doors | United States | Custom Door and Mirror

- Custom Closet Doors | United States | Custom Door and Mirror

Read User Manual Online (PDF format)

Read User Manual Online (PDF format) >>