ROTAX SI-PAC-024 Optional Fuel Pressure Adapter Instruction Manual

- June 8, 2024

- ROTAX

Table of Contents

ROTAX SI-PAC-024 Optional Fuel Pressure Adapter Instruction Manual

SI-PAC-024

ATA System: 73-10-00 Fuel system

1) Planning information

“PAC” Service Instruction Documents provide detailed information on ROTAX® Aircraft Engine Parts and Accessories. Depending on the engine type used with, the referenced parts and accessories may be provided with or without EASA certification or ASTM compliance. Certification / Compliance of referenced Parts and Accessories must in such cases be completed by the aircraft OEM.

To obtain satisfactory results, procedures specified in this publication must be accomplished with accepted methods in accordance with prevailing legal regulations. BRP-Rotax GmbH & Co KG cannot accept any responsibility for the quality of work performed in accomplishing the requirements of this publication.

1.1) Applicability

Refer to the latest issue of the relevant Illustrated Parts Catalog of your

specific engine type.

The optional fuel pressure adapter is not part of the Engine Type Design. Such a PAC part has been then tested and released by BRP-Rotax, but it might not be certified for the relevant engine type.

In such a case the correct function in conjunction with the entire system is the responsibility of the aircraft manufacturer and must be carried out jointly with the aircraft.

1.2) Concurrent ASB/SB/SI and SL

In addition to this Service Instruction – PAC the following Service documents

must be observed and complied with:

in general all relevant Alert Service Bulletins (ASB), Service Bulletins (SB),

Service Instructions (SI), Service Letters (SL), Service Instruction – Parts

and Accessories (SI-PAC).

1.3) Reason

In the course of continuous development and standardization, an optional fuel

pressure adapter has been introduced as an optional extra part.

1.4) Subject

Optional fuel pressure adapter for ROTAX® Aircraft Engines.

1.5) Compliance

None – For Information Only.

1.6) Approval

None.

1.7) Labor time

Estimated labor hours:

Engine installed in the aircraft – – – labor time will depend on airframe

installation and therefore no estimate is available from the engine

manufacturer.

1.8) Mass data

Change of weight – – – none.

Moment of inertia – – – unaffected.

1.9) Electrical load data

No change.

1.10) Software modifications

No change.

1.11) References

In addition to this technical information refer to current issue of

– in general Operators Manual (OM)

– in general Illustrated Parts Catalog (IPC)

– in general Installation Manual (IM)

– in general Maintenance Manual Line (MML)

– in general Maintenance Manual Heavy (MMH)

NOTE: The status of the Manuals can be determined by checking the table

of amendments.

The 1st column of this table shows the revision status. Compare this number to

the one listed on the ROTAX website:

www.flyrotax.com. Updates and current revisions can

be downloaded for free.

1.12) Other Publications affected

None.

1.13) Interchangeability of parts

– All parts are interchangeable

2) Material Information

2.1) Material- cost and availability

Price and availability will be provided on request by ROTAX® Authorized

Distributors or their independent

Service Centers.

2.2) Company support information

– Any possible support by BRP-Rotax will be provided on request by ROTAX®

Authorized Distributors

or their independent Service Centers.

2.3) Material requirement per engine

Parts requirement:

*or equivalent as required by your avionic system and/or aircraft manufacturer.

2.4) Material requirement per spare part

None.

2.5) Rework of parts

None.

2.6) Special tooling/lubricants- /adhesives- /sealing compounds

None.

3) Accomplishment/Instructions

– ROTAX reserves the right to make any amendments to existing documents which

might become necessary due to this standardization, at the time of next

revision or issue.

NOTE: Before maintenance, review the entire documentation to make sure you

have a complete understanding of the procedure and requirements.

Accomplishment

All measures must be implemented and confirmed by at least one of the

following persons or organizations:

– ROTAX® Airworthiness representatives

– ROTAX® – Authorized Distributors or their independent Service Centers

– Persons with approved qualifications for the corresponding engine types.

Only authorized persons (iRMT, Level Heavy Maintenance) are entitled to carry

out this work.

See current Installation Manual (IM) for the respective engine type.

General Further material on general inspection, maintenance and repair can also be found in relevant Advisory Circular AC 43.13 from FAA.

Advisory Circular

The Advisory Circular (AC) contains maintenance methods, techniques and

practices.

3.1) Spare parts – related information

See current Illustrated Parts Catalog (IPC) for the respective engine type.

3.2) Operation – related information

See current Operators Manual (OM) for the respective engine type.

3.3) Installation – related information

See current Installation Manual (IM) for the respective engine type.

3.4) Maintenance (Line) – related information

See current Maintenance Manual Line (MML) for the respective engine type.

3.5) Maintenance (Heavy) – related information

See current Maintenance Manual Heavy (MMH) for the respective engine type.

Before opening the fuel injection system, drain the fuel from engine rail. See relevant Maintenance Manual Line Chapter 12-20-00 section Planned maintenance.

NOTE: Before accomplishment, review the entire documentation to make sure you have a complete understanding of the procedure and requirements.

If the fuel system has already been installed and pressurized, drain the fuel from engine rail. See relevant Maintenance Manual Line Chapter 12-20-00 section Scheduled maintenance

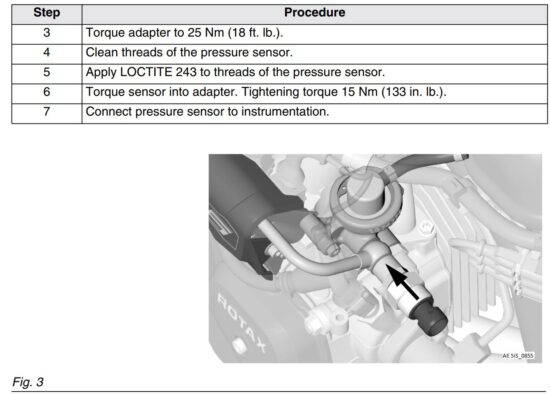

1. Banjo bolt M12x1.5

Fig. 1

ENVIRONMENTAL NOTE

Work with the utmost care to ensure that no water pollutants can penetrate

into the soil, water or the sewerage system.

Dispose of fuel at the respective collecting point or hand it over to an approved disposal company.

3.6) Finishing work

– Restore aircraft to original operating configuration

– Connect negative terminal of aircraft battery

3.7) Test run

In case of uninstalled engines test run can be skipped as this is covered by

the mandatory test run after installation.

Conduct test run and perform leakage check.

See current Maintenance Manual Line (MML) for the respective engine type,

Chapter 12-20-00.

3.8) Summary

The execution of the Service Instruction – PAC must be confirmed in the

logbook.

A revision bar outside of the page margin indicates a change to text or

graphic.

Translation into other languages might be performed in the course of language

localization but does not lie within ROTAX’ scope of responsibility.

In any case the original text in English language and the metric units are

authoritative.

3.9) Inquiries

Inquiries regarding this Service Instruction – PAC should be sent to the

ROTAX® Authorized Distributor of your area.

A list of all ROTAX® Authorized Distributors or their independent Service

Centers is provided on

https://dealerlocator.flyrotax.com.

4) Appendix

The following drawings should convey additional information:

Sensor banjo bolt part no. 841131

Fig. 4

Copyright – BRP-Rotax GmbH & Co KG. All rights reserved.

Read More About This Manual & Download PDF:

References

Read User Manual Online (PDF format)

Read User Manual Online (PDF format) >>