Clarke Tools CBS45MD 4½ X 6 Metal Cutting Bandsaw Instruction Manual

- June 13, 2024

- Clarke Tools

Table of Contents

- INTRODUCTION

- GUARANTEE

- ENVIRONMENTAL PROTECTION

- SAFETY WARNINGS

- SPECIFICATIONS

- ELECTRICAL CONNECTIONS

- OVERVIEW

- ASSEMBLY

- SETUP AND ADJUSTMENTS

- METHODS OF OPERATION

- TROUBLESHOOTING

- MAINTENANCE

- PARTS LIST & DIAGRAM

- DECLARATION OF CONFORMITY

- Read User Manual Online (PDF format)

- Download This Manual (PDF format)

Clarke Tools CBS45MD 4½ X 6 Metal Cutting Bandsaw Instruction Manual

INTRODUCTION

Thank you for purchasing this CLARKE Bandsaw. Before attempting to operate the machine, it is essential that you read this manual thoroughly and carefully follow all instructions given. In doing so you will ensure the safety of yourself and that of others around you, and you can also look forward to the product giving you long and satisfactory service.

GUARANTEE

This CLARKE product is guaranteed against faulty manufacture for a period of 12 months from the date of purchase. Please keep your receipt as proof of purchase. This guarantee is invalid if the product is found to have been abused or tampered with in any way, or not used for the purpose for which it was intended. Faulty goods should be returned to their place of purchase, no product can be returned to us without prior permission. This guarantee does not effect your statutory rights.

ENVIRONMENTAL PROTECTION

Recycle unwanted materials instead of disposing of them as waste. All unwanted

accessories and packaging should be sorted and taken to a recycling centre for

disposal in a manner which is compatible with the environment.

ENVIRONMENTAL RECYCLING POLICY

Through purchase of this product, the customer is taking on the obligation to

deal with the WEEE in accordance with the WEEE regulations in relation to the

treatment, recycling & recovery and environmentally sound disposal of the

WEEE. In effect, this means that this product must not be disposed of with

general household waste but according to the laws governing Waste Electrical

and Electronic Equipment (WEEE) at a recognised disposal facility.

SAFETY WARNINGS

⚠ CAUTION: FAILURE TO FOLLOW THESE PRECAUTIONS COULD RESULT IN PERSONAL INJURY, AND/OR DAMAGE TO PROPERTY.

WORK ENVIRONMENT

- Keep the work area clean and well lit. Cluttered and dark areas invite accidents.

- Do not operate power tools in explosive atmospheres, such as in the presence of flammable liquids, gases or dust. Power tools create sparks which may ignite the dust or fumes.

- Keep children and bystanders away while operating a power tool. Anyone entering the work area must wear personal protective equipment. Distractions can cause you to lose control and fragments of work or a broken disc may fly away and cause injury.

- Store power tools properly when not in use. Abrasive products should be stored in a dry, secure place out of the reach of children.

- Please read these instructions carefully and retain for future reference.

ELECTRICAL SAFETY

- Power tool plugs must match the outlet. Never modify the plug in any way. Do not use adapter plugs with earthed (grounded) power tools. Unmodified plugs and matching outlets will reduce the risk of electric shock.

- Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the risk of electric shock.

- Do not abuse the cable. Never use the cable for carrying, pulling or unplugging the power tool. Keep the cable away from heat, oil, sharp edges or moving parts. Damaged or entangled cables increase the risk of electric shock.

- When operating a power tool outdoors, use an extension cable suitable for outdoor use. Use of a cable suitable for outdoor use reduces the risk of electric shock.

PERSONAL SAFETY

- Stay alert, watch what you are doing and use common sense when operating a power tool. Do not use a power tool while you are tired or under the influence of drugs, alcohol or medication. A moment of inattention while operating power tools may result in personal injury.

- Use personal protective equipment. Always wear eye protection. Safety equipment such as dust mask, non-skid safety shoes, hearing protection and a workshop apron capable of stopping small abrasive or workpiece fragments.

- Avoid accidental starting. Ensure the switch is in the off position before plugging in. Plugging in power tools that have the switch on invites accidents.

- Remove any adjusting key or wrench before turning the power tool on. A wrench or a key left attached to a rotating part of the power tool may result in personal injury.

- Do not overreach. Keep proper footing and balance at all times. This enables better control of the power tool in unexpected situations. Dress properly. Do not wear loose clothing or jewellery.

- Keep your hair, clothing and gloves away from moving parts. Loose clothes, jewellery or long hair can be caught in moving parts. Keep the work area clean and tidy.

- Regularly clean the power tool’s air vents. The motor fan will draw dust inside the housing and accumulation of material could cause electrical hazards.

- Avoid operator fatigue. Stop the power tool at regular intervals for a short break to rest hands and arms.

- Maintain your tools. Keep all handles and grips dry and clean.

ELECTRICAL SAFETY

- Position the power cable so that it cannot be inadvertently pulled or pinched, and where it does not cause a trip hazard.

- This machine is designed for indoor environments and must not be used for other purposes.

- If the machine requires repair, always contact your Clarke dealer. Always insist on original spare parts. Repairs carried out by unauthorized persons may be dangerous and invalidate the guarantee.

- This machine must only be used by adults. Children should not be allowed to play with this product.

- Do not use extension power cables.

- Before cleaning or maintenance tasks, always unplug the machine from the power supply.

POWER TOOL USE AND CARE

- Do not force the machine. Use the correct power tool for your application. It will do a better and safer job at the rate for which it was designed.

- Do not use the power tool if the switch does not turn it on and off. Any power tool that cannot be controlled with the switch is dangerous and must be repaired.

- Disconnect the power tool from the power supply before making any adjustments, changing accessories, or storing the tool. These measures will reduce the risk of the power tool starting accidently.

- Store power tools out of the reach of children and do not allow persons unfamiliar with these instructions to operate the power tool. Power tools are potentially dangerous in the hands of untrained users.

- Maintain power tools in top condition. Keep tools/ machines clean for the best and safest performance. Check for misalignment or binding of moving parts, broken parts, or any condition that may affect the power tool’s operation. If damaged, have the power tool repaired before use. Many accidents are caused by poorly maintained power tools.

- Use recommended accessories. The use of improper accessories could be hazardous.

- Machine cleanliness. Do not allow the ventilation slots in the machine to become blocked with dust.

- Check the power tool for damage before using the machine. Any damaged part should be inspected to ensure that it will operate properly and perform its intended function. Check for alignment of moving parts, breakage of parts, mountings, and any other condition that may affect the machine’s operation. Any damage should be properly repaired or the part replaced. If in doubt, DO NOT use the machine. Consult your local dealer.

SERVICING

- When necessary, have your power tools serviced or repaired by a qualified person using identical replacement parts. This will ensure that the safety of the power tool is maintained.

ADDITIONAL PRECAUTIONS FOR BANDSAWS

- Always check safety guards are in place and functioning correctly before switching the machine on.

- Always use a push stick, especially on small workpieces.

- Always use the appropriate saw blade for the material being cut.

- Never use the machine if the electric cable, plug or motor is in poor condition.

- Never allow the ventilation slots in the motor to become blocked.

- Never touch the blade immediately after use, when changing the blade always allow time for it to cool.

- Never use bent or cracked blades. (Replacement blades are available from your Clarke dealer.

- When cutting wood, ensure all nails or fastenings have been removed beforehand.

- When cutting round stock, use a suitable jig or fixture to keep the work from turning.

- Always ensure the blade is fully tightened and correctly adjusted before use.

- Keep the mains power cable well away from the machine and ensure an adequate electrical supply is close at hand so that the operation is not restricted by the length of the cable.

- Switch the machine off immediately the task is completed.

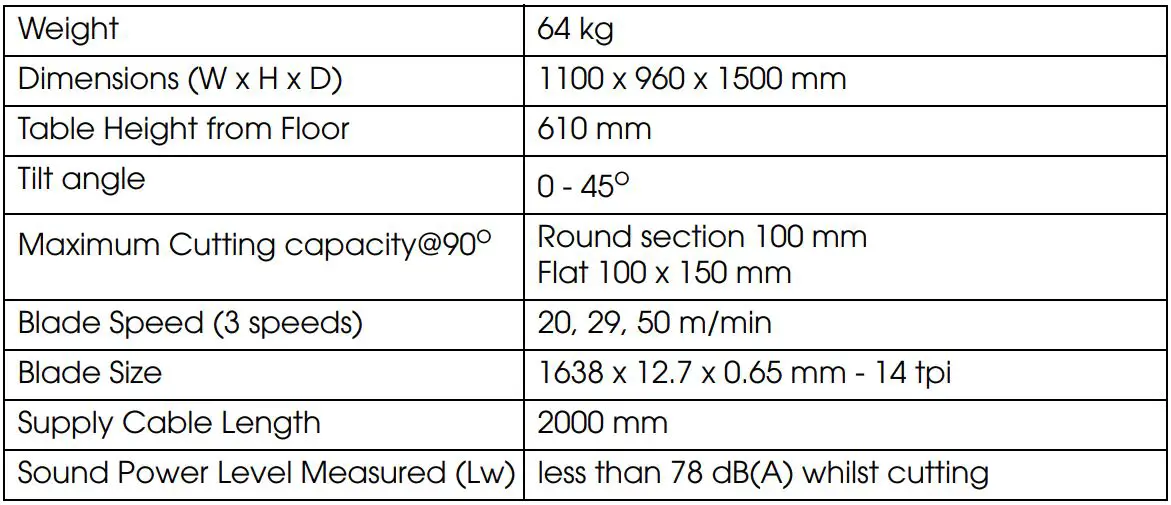

SPECIFICATIONS

ELECTRICAL CONNECTIONS

⚠ WARNING! Read these electrical safety instructions thoroughly before connecting the product to the mains supply.

Before switching the product on, make sure that the voltage of your electricity supply is the same as that indicated on the rating plate. This product is designed to operate on 230VAC 50Hz. Connecting it to any other power source may cause damage.

This product may be fitted with a non-rewireable plug. If it is necessary to change the fuse in the plug, the fuse cover must be refitted. If the fuse cover becomes lost or damaged, the plug must not be used until a suitable replacement is obtained.

If the plug has to be changed because it is not suitable for your socket, or due to damage, it should be cut off and a replacement fitted, following the wiring instructions shown below. The old plug must be disposed of safely, as insertion into a mains socket could cause an electrical hazard.

If the colours of the wires in the power cable of this product do not correspond with the markings on the terminals of your plug, proceed as follows.

- The Blue wire must be connected to the terminal marked N or coloured Black.

- The Brown wire must be connected to the terminal marked L or coloured Red.

- The Yellow and Green wire must be connected to the terminal marked E or or coloured Green. Plug must be BS1363/A approved.

We strongly recommend that this machine is connected to the mains supply via a Residual Current Device (RCD) If in any doubt, consult a qualified electrician. DO NOT attempt any repairs yourself.

OVERVIEW

ASSEMBLY

The bandsaw comes partly assembled. Unpack and lay out all the items and

identify each one, referring to the overview on page 8. If any parts are

missing, immediately contact the dealer where the product was purchased.

⚠ CAUTION: IF THERE IS ANY UNCERTAINTY REGARDING ELECTRICAL CONNECTIONS, YOU

SHOULD CONSULT A QUALIFIED ELECTRICIAN.

LEGS AND TOOL TRAY ASSEMBLY

- The legs are a three sided section, one side of which is hinged.

-

Attach the tool tray between the legs, as shown, (i.e. tray edges uppermost), using the four nuts, bolts and washers supplied. Leave the nuts finger tight at this stage.

NOTE: The special “D” shaped washer should be inside the leg with the nut. -

Gently lower the bandsaw onto the legs.

CAUTION: TWO PEOPLE WILL BE REQUIRED FOR THIS TASK -

Secure the bandsaw to the legs using three nuts, bolts and washers at the top of each leg. Make sure there is no distortion.

NOTE: The machine bed may fit either way round. -

Tighten all the tray nuts and bolts, checking for distortion and stability.

DRIVE GUARD

The drive guard sits over the motor shaft, and the gear-box shaft. The gearbox

shaft extends through a circular plate secured by three screws.

- Remove two of the screws (arrowed) and the guard fixing bolt.

- Lower the drive guard over the shafts. The elongated hole is placed over the motor shaft.

- Replace the screws and the guard fixing bolt to secure the drive guard.

SAFETY SWITCH

For safety purposes, a micro-switch is provided to stop the bandsaw when the

drive guard is opened. The switch is mounted on the inside of the drive guard,

between the two pulleys. The micro-switch is operated by an actuating tab, so

that when the lid is closed, the bandsaw will operate.

- Remove the switch from its mounting by unscrewing the two mounting screws and nuts.

- Thread the wires through the hole in the drive guard complete with the cable gland provided, and connect the two push-on connectors to the micro-switch terminals. Re-tighten the nut on the cable gland.

- Re-fit the switch to the holder using the two mounting screws & nuts. Do not overtighten.

- Close the guard, switch on the machine, and check that the switch operates correctly when the guard is opened and closed.

· It may necessary to bend the switch actuating tab slightly to ensure correct operation.

DRIVE PULLEYS

The drive pulleys may now be fitted.

- The motor pulley is located with a key and grub screw, and a keyway is therefore provided in the bore, whilst the gearbox pulley has no keyway, and is located with a grub-screw on a flat surface milled on the shaft.

IMPORTANT: When fitting, they are mounted in reverse to each other as shown on the table inside the drive guard.

- Fit the gearbox pulley onto its shaft, ensuring the grub screw lines up with the flat on the shaft. Tighten the grub screw fully.

- Fit the motor pulley to its shaft so that it lines up with the gearbox pulley. This may be done with a straight edge across the top of the pulleys to ensure the grooves are in line. When correctly aligned, tighten the grub screw provided.

DRIVE BELT

-

Fit the drive belt, lifting the motor and slipping the belt over the pulleys.

· Belt tension is set by an adjusting bolt through the motor mounting plate. -

Screw the bolt in until the belt can be deflected by approx. ½” at the centre of its span.

-

Lock the adjusting bolt using the locking nut.

NOTE: Do not overtighten the adjusting bolt as this will distort the motor mounting plate.

SWITCH ASSEMBLY

On the left end of the machine is the ON/OFF switch assembly, which is hanging

loose at this stage.

- Connect the two earth wires (1) extending from the back of the switch assembly to the machine bed using the screw and washer provided.

- Mount the switch assembly using the two screws (2).

WORK STOP ASSEMBLY

The work stop is used to cut pieces of equal length without having to measure

each piece individually. It comprises two parts, the work stop, and the

mounting rod.

- Push the rod into the hole in the edge of the vice and secure with the bolt provided.

- Mount the work stop on to the rod, with the flat face towards the saw blade, and temporarily secure with the grub-screw supplied. Ensure it is not pushed on too far, as it may interfere with the saw blade when the saw is lowered.

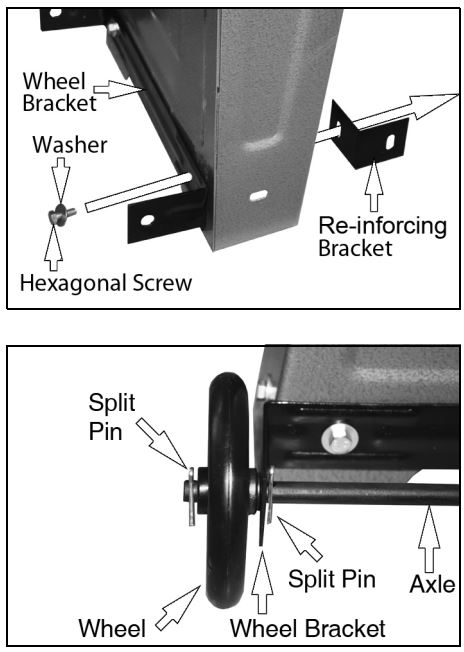

HANDLE AND WHEELS

- Fit the handle by passing the ends of the handle through the corresponding holes in the right leg, and locating from inside the leg using the split pins provided.

- Attach the wheel bracket to the base of the left leg using the nuts, bolts and washers, together with a pair of re-enforcing brackets fitted inside the leg.

- Pass the axle through the holes at the ends of the bracket, and insert the split pins into the holes in the axle nearest the frame.

- Fit the wheels to the axle and secure with the remaining split pins.

- Add the two remaining reinforcing brackets to the bottom of the other legs.

- Finally, carry out a thorough check to ensure that all parts are secure and correctly assembled.

When the machine is lifted using the handle it will automatically pivot on the wheels, allowing the machine to be maneuvered around the workshop.

SETUP AND ADJUSTMENTS

BLADE GUIDE ADJUSTMENT

The blade guides must be correctly aligned for the bandsaw to perform at its

best.

When the saw is used correctly, adjustment is rarely needed. If, for any

reason, the guides do move out of alignment, you must re-adjust them

immediately or the blade will not cut straight and will be damaged.

Guide adjustment is critical to the performance of your saw but it Is always

best to try a new blade to see if this will correct poor cutting before

adjusting the bearings.

If a blade becomes dull on one side, it will begin cutting crooked. A new

blade should correct this problem without the need for guide adjustment. If

not, check the blade guides for accurate spacing.

- The inner guide bearing is fixed and cannot be adjusted.

- The outer guide bearing is mounted to an eccentric bolt and can be adjusted.

- There should be 0.001″ clearance between a 0.025″ thickness blade and the guide bearings.

To obtain this clearance adjust the bearing as follows:

- Loosen the nut whilst holding the bolt with a second spanner as shown.

- Position the eccentric by turning the bolt to the required position before tightening the nut.

- Adjust the other blade guide bearing in the same way.

· The back edge of the blade should just touch the blade guide rear bearing.

BLADE GUIDE ASSEMBLY ADJUSTMENT

The blade guide assemblies are adjustable to accommodate the size of

workpiece. Correct adjustment will help accurate cutting and prolong the life

of the blade.

- Place your workpiece in the vice and clamp tightly.

- Loosen the securing bolts.

- Adjust each blade guide assembly to just clear the workpiece without impeding the lowering arm.

- Tighten the securing bolts.

ADJUSTING BLADE TENSION

The blade needs to be tight enough not to wander or slip. To give a straight

cut;

- The optimum tension is 700-900 kgs, as measured with a blade tension gauge if one is available.

- The adjusting knob is provided with a spring lock to ensure it does not move during use.

- Turn the tension adjusting knob clockwise to increase tension or turn anticlockwise to decrease.

- To tension the blade without using a gauge, slacken off the adjuster so that the blade sags, then screw in again (clockwise) until all sag has been eliminated. Finally, turn the adjuster a further two complete turns.

- If the saw will not be used for some time, e.g. at the end of a working day, it is recommended to relieve the tension on the blade.

BLADE SELECTION

A general purpose blade (14 tooth per inch) is supplied with the saw (see

Specifications). Additional blades,- in 14 and 24 tooth sizes are available

from your local Clarke dealer.

- The choice of blade pitch is governed by the thickness of the work to be cut:- the thinner the workpiece, the more teeth are used.

- A minimum of 3 teeth should be touching the workpiece at all times for satisfactory cutting.

- If the teeth of the blade are so for apart that they straddle the work, as in the case of wire rods/cables, severe damage to the workpiece and to the blade can result.

CHANGING SPEED

CHANGING THE BLADE

If the blade becomes worn or damaged it should be replaced as follows:

-

Disconnect the bandsaw from the power supply.

-

Raise the arm to its vertical position and lock in place by setting the locking bracket in the lower notch in the saw body.

-

Undo the thumbscrew securing the blade safety cover and open the cover.

-

Remove the blade guard attached to the blade guide assembly.

-

Turn the blade tension adjuster knob anticlockwise to slacken the blade and allow removal from the pulleys and from between the guide bearings, paying due care to the sharpness of the teeth.

-

Feed the new blade between the blade guide bearings and over the top pulley.

· Note the direction of the saw teeth in relation to the symbol shown. -

Hold the blade in position with one hand whilst feeding it downwards and over the bottom pulley.

-

Ease the blade onto the pulleys as far as possible.

-

Tension the blade according to the instructions on page 15.

-

Place 2-3 drops of oil on the blade.

-

Re-fit the blade guard and close the blade safety cover.

-

Observing all safety precautions, start the bandsaw and allow to run for a few minutes at low speed in order to bed in the new blade.

-

Once the blade has been replaced it is recommended that the blade is `Run In’ for a few minutes before starting work.

NOTE: If the pulleys have not been interfered with, the blade should run evenly, just off the lip on the back of each pulley. If it wanders off the pulleys, or scuffs against the lip at the back of the pulley, evident by a scraping sound, the tracking will need adjustment see below.

BLADE TRACKING ADJUSTMENT

Blade tracking is carried out at the factory and it should not normally

require re-adjustment. If the blade comes off the pulleys, first try a new

blade, as this should normally cure the problem. If the new blade does not

track correctly, adjust the tracking as follows:

- Disconnect from the power supply, set the saw arm is in the vertical position.

- Open the blade safety cover and adjust the blade to moderate tension.

- Slacken the two bolts, shown by one turn.

- Turn the blade by hand, (taking care of sharp teeth), making sure that the blade runs closely against the lip on the back edge of the pulleys but without rubbing. · If the blade tends to rub hard against the lip on the back edge of the pulleys, a scraping sound will be heard. If this happens, the socket screw shown above should be turned ANTICLOCKWISE until the blade runs evenly on the pulley. Should the blade tend to run off the pulley, turn the socket screw CLOCKWISE.

- Close the blade safety cover. Switch on the saw and test the action of the blade to ensure it runs true.

- If necessary, stop and carry out the adjustment again until satisfied.

ADJUSTING THE BLADE ANGLE

The blade must be at right angles (or vertical) to the machine bed when

cutting horizontally. To achieve this:

- Loosen the bolt shown.

- Adjust the blade guide to make the blade vertical to the bed.

- Re-tighten the bolt.

- Check the blade Is vertical by placing a set-square on the bed. It not, repeat the process 1 to 3.

METHODS OF OPERATION

HORIZONTAL CUTTING

-

Raise the arm until held by the support bracket.

-

Open the vice by turning the handle at the end of the base anticlockwise.

-

Clamp the workpiece securely in the vice by turning the vice handle clockwise. (If the workpiece is long it should be supported).

-

Switch on the bandsaw and slowly lower the saw onto the workpiece.

· Let the weight of the saw provide the cutting force. -

Set the spring tension by turning the weight adjusting handle to set the cutting force of the saw.

· The saw automatically shuts off at the end of the cut when the switch cut- off tip on the arm touches the OFF switch. This can be prevented from happening by increasing the length of the stop bolt. -

Adjust the stop bolt if required and tighten the locking nut to secure.

VERTICAL CUTTING

To operate in the vertical cutting position, the table must be fitted and the

saw body locked in the vertical position.

LOCKING IN THE VERTICAL POSITION

- Rotate the vertical locking bracket to an upright position, and locate in the notch on the saw body.

- If you have difficulty in locating this bracket in the notch, adjust the bracket securing bolt until the bracket locates;- then tighten the bracket securing bolt.

FITTING THE TABLE

- Remove the screws from the blade guide.

- Attach the table support bracket to the bolt as shown, but leaving the bolt slack.

- Set the table on top of the guide assembly and insert screws A into the guard.

- Fit screw B (with the nut and washer), into the bracket and tighten fully.

- When cutting, adjust the upper blade guide so that no more blade is exposed than is required to cut the workpiece.

- Keep hands well clear of the blade and use a push stick for small workpieces.

- Switch off immediately when cutting is complete.

TROUBLESHOOTING

MAINTENANCE

⚠ WARNING: ALWAYS SWITCH OFF AND DISCONNECT FROM THE POWER SUPPLY BEFORE CARRYING OUT ANY CLEANING OR MAINTENANCE TASKS.

GENERAL

Remove all accumulated swarf from inside the bandsaw frequently using a soft

brush and/or vacuum cleaner. Alternatively, if compressed air is used, ensure

it is set to no more than 10 psi and wear protective safety glasses. Maintain

a thin film of oil on all unpainted surfaces including all screw threads to

protect your saw from corrosion. · All bearings are lubricated for life and

require no maintenance.

GEARBOX

The drive gears run in an oil bath and will not require a lubricant change

more often than once a year if in daily use. To change the oil proceed as

follows:

- Lower the saw to a horizontal position and remove the four bolts securing the gearbox cover.

- Remove the gearbox cover.

- Place a container under the right lower corner of the gear box and slowly raise the bandsaw until the oil drains into the container.

- Lower the saw and wipe up any excess oil and foreign matter with a soft rag.

- Replace the oil with a similar quantity until the drive gears are covered.

- Replace the cover and gasket and tighten the four bolts.

STORAGE

When storing the bandsaw, disconnect the power cable, cover the machine with a

plastic sheet and store it in a dry location.

PARTS LIST & DIAGRAM

When requesting replacement parts please quote: SD45001 – 109.

Replacement Blades and sundries are available from your Clarke dealer;

Blade (14tpi) 1 per pack Blade (24tpi) 1 per pack

Part no 65009695 Part no 65021135

Replacement drive belts Clarke cutting oil ref: 1 Litre Clarke cutting oil

ref: 5 Litre

Part no 2100112 Part no 3051059 Part no 3051061

DECLARATION OF CONFORMITY

Parts & Service: 020 8988 7400 / E-mail:

Parts@clarkeinternational.com or

Service@clarkeinternational.com

Read User Manual Online (PDF format)

Read User Manual Online (PDF format) >>