EGO COMMERCIL BCX4500 Volt Lithium Ion Commercial Brushcutter Instruction Manual

- June 16, 2024

- EGO COMMERCIL

Table of Contents

- EGO COMMERCIL BCX4500 Volt Lithium Ion Commercial Brushcutter

- Product Information

- Product Usage Instructions

- SAFETY INSTRUCTIONS

- SPECIFICATIONS

- PACKING LIST

- DESCRIPTION

- ASSEMBLY

- OPERATION

- BATTERY-STATUS INDICATOR AND SPEED INDICATOR

- MAINTENANCE

- TROUBLESHOOTING

- WARRANTY POLICY

- PRODUCT WARRANTY TABLE

- References

- Read User Manual Online (PDF format)

- Download This Manual (PDF format)

EGO COMMERCIL BCX4500 Volt Lithium Ion Commercial Brushcutter

Product Information

Specifications:

- Model Number: BCX4500

- Battery Type: 56 Volt Lithium-ion

- Product Type: Commercial Brushcutter

Product Usage Instructions

Safety Instructions

Before using this product, it is important to read and understand all safety

instructions provided in the Operator’s Manual. Failure to follow these

instructions may result in electric shock, fire, and/or serious personal

injury. Some important safety instructions include:

- Always wear safety goggles or safety glasses with side shields and a full face shield when operating the brushcutter to protect your eyes from potential debris.

- Do not operate the brushcutter near electronic devices such as pacemakers, as it may cause interference or failure of the pacemaker. Consult your physician if you have any electronic devices.

- All repairs and replacements should be performed by a qualified service technician to ensure safety and reliability.

Assembly

Before using the brushcutter, follow these steps to assemble it:

- Attach the bike handle to the power head using the wing bolt (B1 and B2).

- Secure the clamp wire loop and blade sheath (C1 and C2).

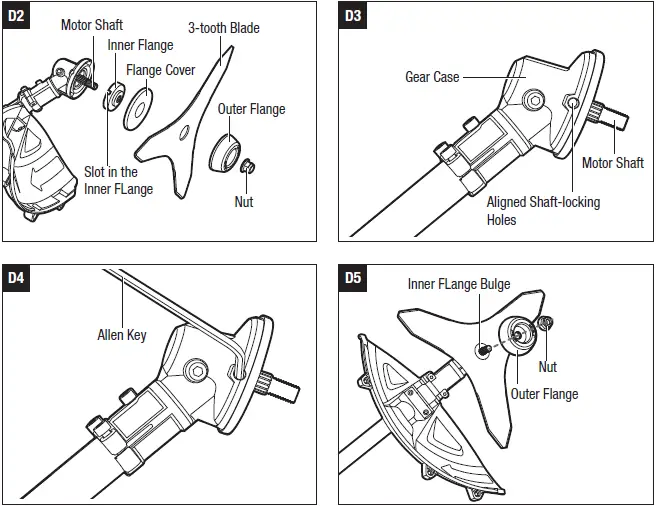

- Attach the blade to the motor shaft, making sure it is aligned with the shaft-locking holes (D1).

- Place the inner flange, flange cover, and outer flange on the motor shaft (D2).

- Secure the inner flange nut using the provided Allen key (D3 and D4).

- Attach the trimmer head to the motor shaft (L).

Operation

Follow these steps to operate the brushcutter:

- Before starting, ensure the battery is fully charged and properly inserted into the battery compartment.

- To turn on the brushcutter, press and hold the lock-off lever (H1) and then squeeze the trigger switch (H2).

- Use the speed mode button (H) to adjust the cutting speed. The speed indicator (I) will display the selected speed mode.

- Hold the bike handle firmly and position the blade near the area to be cut.

- Move the brushcutter back and forth in a sweeping motion to effectively cut through grass or vegetation.

- Always wear appropriate protective gear, such as gloves, long pants, and closed-toe shoes, while operating the brushcutter.

FAQ

-

Q: Can I use this brushcutter without a shoulder strap?

A: While it is not required to use a shoulder strap, we recommend using one for added comfort and stability during extended use. -

Q: How do I change the blade?

A: To change the blade, follow these steps:

1. Disconnect the brushcutter from the power source.

2. Remove the outer flange nut using the provided hex key.

3. Remove the flange cover, inner flange, and old blade.

4. Attach the new blade, ensuring it is aligned with the shaft-locking holes.

5. Secure the blade by tightening the outer flange nut.-

Q: How often should I recharge the battery?

A: It is recommended to recharge the battery after each use. However, if the battery is not fully depleted, you can recharge it as needed. -

Q: Can I use this brushcutter for trimming edges?

A: Yes, this brushcutter can be used for trimming edges by attaching the trimmer head and adjusting the cutting height accordingly.

WARNING:

To reduce the risk of injury, the user must read and understand the Operator’s

Manual before using this product. Save these instructions for future

reference.

READ ALL INSTRUCTIONS!

READ OPERATOR’S MANUAL

Residual risk! People with electronic devices, such as pacemakers, should

consult their physician(s) before using this product. Operation of electrical

equipment in close proximity to a heart pacemaker could cause interference or

failure of the pacemaker.

WARNING: To ensure safety and reliability, all repairs and replacements should

be performed by a qualified service technician.

SAFETY SYMBOLS

The purpose of safety symbols is to attract your attention to possible

dangers. The safety symbols and the explanations with them deserve your

careful attention and understanding. The symbol warnings do not, by

themselves, eliminate any danger.

The instructions and warnings they give are no substitutes for proper accident

prevention measures.

WARNING: Be sure to read and understand all safety instructions in this

Operator’s Manual, including all safety alert symbols such as “DANGER,”

“WARNING,” and “CAUTION” before using this tool. Failure to follow all

instructions listed below may result in electric shock, fire, and/or serious

personal injury.

SYMBOL MEANING

SAFETY ALERT SYMBOL: Indicates DANGER, WARNING, or CAUTION, may be used in conjunction with other symbols or pictographs.

WARNING:

The operation of any power tools can result in foreign objects being thrown

into your eyes, which can result in severe eye damage. Before beginning power

tool operation, always wear safety goggles or safety glasses with side shields

and a full face shield when needed. We recommend a Wide Vision Safety Mask for

use over eyeglasses or standard safety glasses with side shields.

SAFETY INSTRUCTIONS

This page depicts and describes safety symbols that may appear on this product. Read, understand, and follow all instructions on the machine before attempting to assemble and operate.

NOTE:

The Bluetooth® word mark and logos are registered trademarks owned by

Bluetooth SIG, inc. and any use of such marks by EGO is under license.

GENERAL MACHINE SAFETY WARNINGS

WARNING:

Read all safety warnings, instructions, illustrations and specifications

provided with this machine. Failure to follow all instructions listed below

may result in electric shock, fire and/or serious injury.

SAVE ALL WARNINGS AND INSTRUCTIONS FOR FUTURE REFERENCE.

The term “machine” in the warnings refers to your mains-operated (corded)

machine or battery-operated (cordless) machine.

Work area safety

- Keep work area clean and well lit. Cluttered or dark areas invite accidents.

- Do not operate machines in explosive atmospheres, such as in the presence of flammable liquids, gases or dust. Machines create sparks which may ignite the dust or fumes.

- Keep children and bystanders away while operating a machine. Distractions can cause you to lose control.

Electrical safety

- Machine plugs must match the outlet. Never modify the plug in any way. Do not use any adapter plugs with earthed (grounded) machines. Unmodified plugs and matching outlets will reduce risk of electric shock.

- Avoid body contact with earthed or grounded surfaces, such as pipes, radiators, ranges and refrigerators. There is an increased risk of electric shock if your body is earthed or grounded.

- Do not operate the machine in rain or wet conditions. Water entering the machine may increase the risk of electric shock or malfunction that could result in personal injury.

- Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the machine. Keep cord away from heat, oil, sharp edges or moving parts. Damaged or entangled cords increase the risk of electric shock.

- When operating a machine outdoors, use an extension cord suitable for outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

- If operating a machine in a damp location is unavoidable, use a ground fault circuit interrupter (GFCI) protected supply. Use of a GFCI reduces the risk of electric shock.

Personal safety

- Stay alert, watch what you are doing and use common sense when operating a machine. Do not use a machine while you are tired or under the influence of drugs, alcohol or medication. A moment of inattention while operating machines may result in serious personal injury.

- Use personal protective equipment. Always wear eye protection. Protective equipment such as a dust mask, non-skid safety shoes, hard hat or hearing protection used for appropriate conditions will reduce personal injuries.

- Prevent unintentional starting. Ensure the switch is in the off-position before connecting to power source and/or battery pack, picking up or carrying the machine. Carrying machines with your finger on the switch or energizing machines that have the switch on invites accidents.

- Remove any adjusting key or wrench before turning the machine on. A wrench or a key left attached to a rotating part of the machine may result in personal injury.

- Do not overreach. Keep proper footing and balance at all times. This enables better control of the machine in unexpected situations.

- Dress properly. Do not wear loose clothing or jewelry. Keep your hair and clothing away from moving parts. Loose clothes, jewelry or long hair can be caught in moving parts.

- If devices are provided for the connection of dust extraction and collection facilities, ensure these are connected and properly used. The use of dust collection can reduce dust-related hazards.

- Do not let familiarity gained from frequent use of machines allow you to become complacent and ignore machine safety principles. A careless action can cause severe injury within a fraction of a second.

Machine use and care

- Do not force the machine. Use the correct machine for your application. The correct machine will do the job better and safer at the rate for which it was designed.

- Do not use the machine if the switch does not turn it on and off. Any machine that cannot be controlled with the switch is dangerous and must be repaired.

- Disconnect the plug from the power source and/or remove the battery pack, if detachable, from the machine before making any adjustments, changing accessories, or storing machines. Such preventive safety measures reduce the risk of starting the machine accidentally.

- Store idle machines out of the reach of children and do not allow persons unfamiliar with the machine or these instructions to operate the machine. Machines are dangerous in the hands of untrained users.

- Maintained machines and accessories. Check for misalignment or binding of moving parts, breakage of parts and any other condition that may affect the machine’s operation. If damaged, have the machine repaired before use. Many accidents are caused by poorly maintained machines.

- Keep cutting machines sharp and clean. Properly maintained cutting machines with sharp cutting edges are less likely to bind and are easier to control.

- Use the machine, accessories and machine bits etc. by these instructions, taking into account the working conditions and the work to be performed. Use of the machine for operations different from those intended could result in a hazardous situation.

- Keep handles and grasping surfaces dry, clean and free from oil and grease. Slippery handles and grasping surfaces do not allow for safe handling and control of the machine in unexpected situations.

Battery machine use and care

- Recharge only with the charger specified by the manufacturer. A charger that is suitable for one type of battery pack may create a risk of fire when used with another battery pack.

- Use machines only with specifically designated battery packs. Use of any other battery packs may create a risk of injury and fire.

- When the battery pack is not in use, keep it away from other metal objects, like paper clips, coins, keys, nails, screws or other small metal objects, that can make a connection from one terminal to another. Shorting the battery terminals together may cause burns or a fire.

- Under abusive conditions, liquid may be ejected from the battery; avoid contact. If contact accidentally occurs, flush with water. If liquid contacts eyes, additionally seek medical help. Liquid ejected from the battery may cause irritation or burns.

- Do not use a battery pack or machine that is damaged or modified. Damaged or modified batteries may exhibit unpredictable behavior resulting in fire, explosion or risk of injury.

- Do not expose a battery pack or machine to fire or excessive temperature. Exposure to fire or temperature above 130 °C may cause an explosion.

- Follow all charging instructions and do not charge the battery pack or machine outside the temperature range specified in the instructions. Charging improperly or at temperatures outside the specified range may damage the battery and increase the risk of fire.

Service

- Have your machine serviced by a qualified repair person using only identical replacement parts. This will ensure that the safety of the machine is maintained.

- Never service damaged battery packs. Service of battery packs should only be performed by the manufacturer or authorized service providers.

STRING TRIMMER AND BRUSHCUTTER SAFETY WARNINGS

- Do not use the machine in bad weather conditions, especially when there is a risk of lightning. This decreases the risk of being struck by lightning.

- Thoroughly inspect the area for wildlife where the machine is to be used. Wildlife may be injured by the machine during operation.

- Thoroughly inspect the area where the machine is to be used and remove all stones, sticks, wires, bones, and other foreign objects. Thrown objects can cause personal injury.

- Before using the machine, always visually inspect to see that the cutter or blade and the cutter or blade assembly are not damaged. Damaged parts increase the risk of injury.

- Follow instructions for changing accessories. Improperly tightened blade securing nuts or bolts may either damage the blade or result in it becoming detached.

- The rated rotational speed of the blade must be at least equal to the maximum rotational speed marked on the machine. Blades running faster than their rated rotational speed can break and fly apart.

- Wear eye, ear, head and hand protection. Adequate protective equipment will reduce personal injury by flying debris or accidental contact with the cutting line or blade.

- While operating the machine, always wear non-slip and protective footwear. Do not operate the machine when barefoot or wearing open sandals. This reduces the chance of injury to the feet from contact with the moving cutters, line or blade.

- While operating the machine, always wear safety footwear. Do not operate the machine when barefoot or wearing open sandals. This reduces the chance of injury to the feet from contact with a moving cutter, line or blade.

- While operating the machine, always wear long trousers. Exposed skin increases the likelihood of injury from thrown objects.

- Keep bystanders away while operating the machine. Thrown debris can result in serious personal injury.

- Always use two hands when operating the machine. Holding the machine with both hands will avoid loss of control.

- Hold the machine by the insulated gripping surfaces only, because the cutting line or blade may contact hidden wiring. Cutting line or blades contacting a “live” wire may make exposed metal parts of the machine “live” and could give the operator an electric shock

- Always keep proper footing and operate the machine only when standing on the ground. Slippery or unstable surfaces may cause a loss of balance or control of the machine.

- Do not operate the machine on excessively steep slopes. This reduces the risk of loss of control, slipping and falling which may result in personal injury.

- When working on slopes, always be sure of your footing, always work across the face of slopes, never up or down and exercise extreme caution when changing direction. This reduces the risk of loss of control, slipping and falling which may result in personal injury.

- Keep all parts of the body away from the cutter, line or blade when the machine is operating. Before you start the machine, make sure the cutter, line or blade is not contacting anything. A moment of inattention while operating the machine may result in injury to yourself or others.

- Do not operate the machine above waist height. This helps prevent unintended cutter or blade contact and enables better control of the machine in unexpected situations.

- When cutting brush or saplings that are under tension, be alert for springback. When the tension in the wood fibers is released, the brush or sapling may strike the operator and/or throw the machine out of control.

- Use extreme caution when cutting brush and saplings. The slender material may catch the blade and be whipped toward you or pull you off balance.

- Maintain control of the machine and do not touch cutters, lines or blades and other hazardous moving parts while they are still in motion. This reduces the risk of injury from moving parts.

- Carry the machine with the machine switched off and away from your body. Proper handling of the machine will reduce the likelihood of accidental contact with a moving cutter, line or blade

- Only use replacement cutters, lines, cutting heads and blades specified by the manufacturer. Incorrect replacement parts may increase the risk of breakage and injury.

- When clearing jammed material or servicing the machine, make sure the switch is off and the battery pack is removed. Unexpected starting of the machine while clearing jammed material or servicing may result in serious personal injury.

- When transporting or storing the machine, always fit the cover on metal blades. Proper handling of the machine will reduce the likelihood of accidental contact with the blade.

- Damage to Trimmer – If you strike a foreign object with the trimmer or it becomes entangled, stop the machine immediately, check for damage and have any damage repaired before further operation is attempted. Do not operate with a broken guard or spool.

- If the equipment should start to vibrate abnormally, stop the motor and check immediately for the cause. Vibration is generally a warning of trouble. A loose head may vibrate, crack, break or come off the trimmer, which may result in serious or fatal injury. Make sure that the cutting attachment is properly fixed in position. If the head loosens after fixing it in position, replace it immediately. Never use a trimmer with a loose cutting attachment.

- Use only with the battery packs and chargers listed below:

| BATTERY PACK | CHARGER |

|---|---|

| BA1400, BA1400T, BA2800, | CH2100E, CH5500E, |

| BA2800T, BA4200, BA4200T, | CH7000E |

| BA5600T, BA6720T | |

| BAX1501 | CHX5500 |

Blade thrust causes and related warnings

Blade thrust is a sudden sideways, forward or backward motion of the machine,

which may occur when the blade jams or catches on an object such as a sapling

or a tree stump. It can be violent enough to cause the machine and/or operator

to be propelled in any direction, and possibly lose control of the machine.

Blade thrust and its related hazards can be avoided by taking proper precautions as given below.

- Maintain a firm grip with both hands on the machine and position your arms to resist blade thrust. Position your body to the left side of the machine. Blade thrust can increase the risk of injury due to the machine moving unexpectedly. Blade thrust can be controlled by the operator if proper precautions are taken.

- If the blade binds, or when interrupting a cut for any reason, switch the machine off and hold the machine motionless in the material until the blade comes to a complete stop. While the blade is binding, never attempt to remove the machine from the material or pull the machine backward while the blade is in motion, otherwise blade thrust may occur. Investigate and take corrective actions to eliminate the cause of blade binding.

- Do not use blunt or damaged blades. Blunt or damaged blades increase the risk of jamming or catching on an object, resulting in blade thrust.

- Always maintain good visibility of the material being cut. Blade thrust is more likely to occur in areas where it is difficult to see the material being cut.

- If you are approached by another person while operating the machine, switch the machine off. There is an increased risk of injury to other persons being struck by the moving blade in the event of blade thrust.

SAVE THESE INSTRUCTIONS!

SPECIFICATIONS

| Voltage | 56 V |

|---|

n0

| 1: 3500 /min

2: 4500 /min

3: 5200 /min

Cutting Mechanism| 3-tooth metal blade

Cutting Swath| 30 cm

Ingress Protection Rating| IPX5* (Protection from water jets)

Recommended Operating Temperature| ****

0 – 40 °C

Recommended Storage Temperature| -20 – 70 °C

Weight (without battery pack)| 5.4 kg

NOTE: IPX5 rating is based on the machine and battery being used together as a system.

Recommended Accessories

| PART NAME | MODEL NUMBER |

|---|---|

| Brushcutter blade | ABB1203-2 |

PACKING LIST

| PART NAME | QUANTITY |

|---|---|

| Brushcutter | 1 |

| Blade and Blade Sheath Set | 1 |

| Guard | 1 |

| Double-shoulder Strap | 1 |

| Hex Key (4 mm) | 1 |

| Multi-function Wrench | 1 |

| Operator’s Manual | 1 |

DESCRIPTION

KNOW YOUR BRUSHCUTTER (Fig. A)

- WARNING: Never operate the machine without the guard firmly in place. The guard must always be on the machine to protect the user.

- WARNING: When the tool is equipped with a trimmer head, the guard accessory with line–cutting blade should be mounted onto the guard. Failure to comply will result in overly long cutting line and overload the motor. Never use the trimmer head without guard accessory.

ASSEMBLY

- WARNING: If any parts are damaged or missing, do not operate this product until the parts are replaced. Use of this product with damaged or missing parts could result in serious personal injury.

- WARNING: Do not attempt to modify this product or create accessories not recommended for use with this product. Any such alteration or modification is misused and could result in a hazardous condition leading to possible serious personal injury.

- WARNING: Always wear heavy gloves when performing any maintenance on the blade. Be careful of the blade and protect your hands from being injured by the blade.

- WARNING: To prevent accidental starting that could cause serious personal injury, always remove the battery pack from the machine when assembling parts, making adjustments, cleaning, or when not in use.

ADJUSTING THE BIKE HANDLE

WARNING:

Always remove the battery pack from the product when you are assembling parts,

making adjustments, cleaning, or when the product is not in use.

- During shipping, the bike handle is mounted on the shaft as shown in Fig.B1

- Loosen the wing bolt on the bracket and then lift the bike handle 180° around the shaft as shown in Fig. B2.

- Turn the handle 90° COUNTERCLOCKWISE to make it face the cutter (Fig. B3).

- Tighten the wing bolt to secure the bike handle in place.

- WARNING: Risk of serious personal injury.

- Only start the tool when the bike handle is adjusted perpendicular to the pole and the operator holds it with both hands.

MOUNTING THE GUARD

WARNING:

To reduce the risk of injury to people, do not operate without guard in place.

- Loosen the two bolts in the guard with the supplied hex key, then remove the bolts and spring washers from the guard (Fig.C1)

- Lift the cutter head and face it downward. Align the two mounting holes in the guard with the two assembly holes in the base of the shaft and then secure the guard onto the shaft base with the two screws and two spring washers (Fig.C2).

- NOTICE: There are two kinds of guards compatible with this machine. The guard with the icon can only be used with the string trimmer head and must not be used with the brusher cutter head. Be careful to choose the correct guard when using the machine.

- NOTICE: The string trimmer guard is not included (EGO AD4500, sold separately).

MOUNTING THE BLADE

- The blade is shipped with a sheath. Before mounting the blade onto the brushcutter, the sheath should be removed by undoing the clamp wire from the loop on the sheath (Fig. D1).

- Familiarize yourself the cutting head assembly shown in Fig. D2. Before mounting the blade, make sure that the inner flange and the flange cover are positioned correctly on the motor shaft (Fig.D2).

- Rotate the motor shaft to align the slot in the inner flange with the shaft-lock access hole in the gear case (Fig. D3).

- Insert the included hex key into the aligned holes to act as a shaft lock (Fig. D4).

- Mount the blade onto the motor shaft, ensuring that the surface of the blade is flush with the surface of the inner flange bulge. Mount the outer flange and the nut (Fig. D5). Finger-tighten the nut in the COUNTERCLOCKWISE direction.

- Position the gear case against a solid surface for support. With one hand grasping the blade and using the other hand to grasp the multi-function wrench to tighten the nut following the directional arrow icon marked on the outer flange (Fig. D6).

ATTACHING/DETACHING BATTERY

NOTE: Fully charge battery pack before first use.

To Attach

Align the battery ribs with the mounting slots in the machine’s battery port

and slide the battery pack until it snaps into position (Fig. E1).

To Detach

Always be aware of the location of your feet, children, or pets when pressing

the battery-release button. Serious injury could result if the battery pack

falls.

NEVER remove the battery pack at a high location.

- Depress the battery-released button and the battery pack will disengage from the latch (Fig. E2).

- Grasp the battery pack and remove it from the machine.

MOUNTING THE DOUBLE-SHOULDER STRAP

- Put the double-shoulder strap on your body and insert the two parts of the strap buckle into each other until a click is heard (Fig.F1).

- Insert the carabiner hook of the hip pad into the hole of the shoulder strap loop fixed on the shaft, and press the shaft down softly (Fig.F2 & F3 & F4).

- Hold the brushcutter with both hands on the right side of your body (Fig. F5). The blade should be parallel to the ground at a proper cutting distance without the need for the operator to bend over.

- Releasing the brushcutter can be achieved in two ways: release the strap buckle (Fig. F6) or press the carabiner of the strap and remove the hook from the loop fixed on the shaft (Fig. F2).

- WARNING: When an emergency occurs, take it off from your shoulder immediately, no matter what way the strap is in. Releasing the strap buckle (Fig.F6) and both hands taking off your shoulders at each side is a quick release method.

- WARNING: You should not use the single-shoulder strap and double-shoulder strap simultaneously.

- NOTICE: When wearing the strap, no other wearable interferes with the release and removal of the strap.

OPERATION

- WARNING: Do not allow familiarity with this product to make you careless.

- Remember that a careless fraction of a second is sufficient to inflict serious injury.

- WARNING: Always wear eye protection along with hearing protection. Failure to do so could result in objects being thrown into your eyes and other possible serious injuries.

- WARNING: Do not use any attachments or accessories not recommended by the manufacturer of this product. The use of attachments or accessories not recommended can result in serious personal injury.

- WARNING: To prevent serious personal injury, remove the battery back from the machine before servicing, cleaning, changing attachments or removing material from the unit.

APPLICATIONS

You may use this product for the purposes listed below:

- With 3-tooth metal blade (original configuration): Cutting grass, weeds, wild growth, and scrub, thinning young stands with a maximum stem diameter of 2 cm.

- With trimmer Head (sold separately): Trimming grass and weeds from around porches, fences, and decks.

- NOTICE: The machine is to be used only for its prescribed purpose. Any other use is deemed to be a case of misuse.

HOLDING THE BRUSHCUTTER (Fig.G)

WARNING:

Dress properly to reduce the risk of injury when operating this machine. Do

not wear loose clothing or jewelry. Wear eye and ear/hearing protectors. Wear

heavy, long pants, boots and gloves. Do not wear short pants or sandals or go

barefoot.

Hold the brushcutter with both hands on the right side of your body. Keep a firm grip with both hands while operating the machine. The blade or the trimmer head should be parallel to the ground at a proper cutting distance without the need for the operator to bend over.

USING THE BRUSHCUTTER

To cut wild growth and scrub, lower the rotating blade down onto the ground to

achieve a chopping effect. Use the brush cutter like a scythe (sweep it to the

right and left) at ground level. Do not use the cutting attachment above waist

height.

- WARNING: The higher the cutting attachment is off the ground, the greater the risk of injury from cuttings being thrown sideways.

- WARNING: When cutting young stands or other woody materials up to 2 cm in diameter, use the left side of the blade to avoid blade thrust situations. Do not attempt to cut woody material with a larger diameter, since the blade may catch or jerk the brushcutter forward. This may cause damage to the blade or the brushcutter or loss of control of the brushcutter, resulting in personal injury.

- WARNING: Thrown parts may seriously injure the operator or bystander. To reduce the risk of personal injury, it is essential to take the following precautions:

- Avoid contact with hard or solid foreign objects such as stones, rocks, or pieces of metal.

- Never cut wood or shrubs with a stem diameter of more than 2 cm.

- Inspect the blade at a regular short interval for signs of damage. Do not continue working with a damaged blade.

- Have the blade resharpened regularly (when it has dulled noticeably) and balanced if necessary (should be performed by a qualified service technician).

BLADE THRUST

Exercise extreme caution when using this unit. Blade thrust is the reaction

that may occur when the spinning blade contacts anything it cannot cut. This

contact may cause the blade to stop for an instant and suddenly “thrust” the

unit away from the object that was hit. This reaction can be violent enough to

cause the operator to lose control of the unit. Blade thrust can occur without

warning if the blade snags, stalls, or binds. This is more likely to occur in

areas where it is difficult to see the material being cut. For cutting ease

and safety, approach the weeds being cut with the brushcutter from the right

to the left. In the event an unexpected object or woody stock is encountered,

this practice could minimize the blade thrust reaction.

Before each use check for damaged/worn parts

Check the blade, guard, and bike handle and replace any parts that are

cracked, warped, bent, or damaged in any away. The edge of the blade can dull

over time. It is recommended that you turn over the blade to extend the life

of the blade and periodically sharpen it (performed by a qualified service

technician) or replace it with a new blade when necessary.

Clean the brushcutter after each use

See the MAINTENANCE section for cleaning instructions.

WARNING:

Ensure the blade has come to a complete stop before cleaning or servicing the

brushcutter. Failure to comply could result in possible serious personal

injury.

Check for blockage of the 3-tooth blade

To prevent blockage, keep the blade clean. Remove grass clippings, leaves,

dirt and any other accumulated debris before and after each use. When a

blockage happens, stop the brushcutter and remove the battery. Then remove any

grass that may have wrapped itself around the motor shaft or the blade.

STARTING/STOPPING THE MACHINE

WARNING:

Dress properly to reduce the risk of injury when operating this machine. Do

not wear loose clothing or jewelry. Wear eye and ear/hearing protection. Wear

heavy-duty, long trousers, boots and gloves. Do not wear short trousers,

sandals or go barefoot.

To start the machine (Fig.H).

- Move the lock-off lever up until it completely fits into the groove, hold it in that position and then press the trigger switch to start.

- The rotational speed of the cutting unit is controlled by the trigger switch. More pressure on the trigger results in higher speed; less pressure on the trigger results in lower speed. Adjust the speed to suit the task at hand.

NOTICE:

The motor starts only when the lock-off lever is moved into the groove and the

trigger switch is depressed at the same time.

To stop the machine

Move the machine away from the cutting area and release the trigger switch to

stop it.

WARNING:

Always remove the battery pack from the machine during work breaks and after

finishing work.

CHANGING SPEED MODE (Fig.I).

- This machine features three-speed modes.

- The speed mode will change with every press of the speed mode button.

- The speed indicator will display the active speed mode: one light for low speed, two lights for medium speed, and three lights for high speed. The low-speed mode provides better control of the machine and longer operating time per charge.

NOTE:

The speed mode can be set before the machine is turned on OR during operation.

When the machine is re-started after a break, the speed mode will return to the previous speed.

BATTERY-STATUS INDICATOR AND SPEED INDICATOR

BATTERY-STATUS INDICATOR AND SPEED INDICATOR (FIG. I).

The battery status indicator shows the charge level and the working status of

the battery pack, and the speed indicator shows the working status of the

machine as shown in the chart below. The battery-status indicator and the

speed indicator will illuminate when the machine is started.

-

Battery High-Temperature Protection

If the battery temperature exceeds 70°C during operation, the temperature protection circuit will immediately shut off the machine to protect the battery pack from overheating damage. The battery-status indicator will glow solid orange. Release the trigger and wait until the overheated battery cools down and the indicator turns green, then restart the machine. -

Battery Electronics Error Protection

When the battery pack electronics error occurs, the battery status indicator will flash red/green alternately and the machine will shut off in 3 seconds. Replace the battery pack or contact the EGO customer service center. -

Machine Overload Protection

This machine features built-in overload circuit protection. When the machine is overloaded, the motor will stop and the battery-status indicator will flash orange. Remove the battery pack from the machine, then reattach the battery pack and restart the machine. Decrease the load on the machine, avoid too long or cutting of the heavy/ woody shrubs, or oversize cutting line (when the machine is used as a string trimmer). -

Machine High-Temperature Protection

If the machine temperature exceeds 90°C during operation, the temperature protection circuit will immediately shut off the machine to prevent overheating damage. The speed indicator will glow solid orange. Release the trigger and wait until the overheated machine cools down and the speed indicator turns green, then restart the machine.

Tips for best brush-cutting

- Always hold the brush cutter on your right side with both hands when operating. Use a firm grip on both handles.

- Maintain your grip and balance on both feet. Position yourself so that you will not be drawn off balance by the kickback reaction of the cutting blade.

- Inspect and clear the area of any hidden objects such as glass, rocks, concrete, fencing, wire, wood, metal, etc., which can be thrown or entangled in the blade.

- Never use blades near sidewalks, fencing, posts, buildings or other immovable objects.

- Never use a blade after hitting a hard object without first inspecting it for damage. Do not use if any damage is detected.

- Use the unit for cutting from the right to the left in a broad sweeping action from side to side.

- Use only the EGOTM blade. Using any other brand blade with this brushcutter could result in serious personal injury.

CONVERTING THE MACHINE TO A STRING TRIMMER

This brushcutter can be converted into a string trimmer using the EGO kit

AH3810 (Sold Separately). The required steps are:

- Replacement of the metal blade with a string trimmer head.

- Replacement of the brushcutter guard with the string trimmer guard.

REPLACE THE 3-TOOTH BLADE WITH THE STRING TRIMMER

HEAD (EGO KIT AH3810, SOLD SEPARATELY)

Familiarize yourself with the cutter head by referring to Fig. J1.

Follow the steps below to remove the 3-tooth blade and mount the trimmer head.

- Disconnect the battery pack.

- Rotate the outer flange to align the slot in the inner flange with the shaft-locking hole in the gear case and insert the included hex key into the aligned holes to act as a stabilizer.

- Wear gloves. Position the gear case against a solid surface for support. Use one hand to grasp the blade and the other hand to loosen the nut in the direction of the arrow marked on the outer flange, using the included multi-function wrench. Remove the 3-tooth blade, nut, and outer flange and save them for reassembly (Fig. J2 & J3).

- Before mounting the trimmer head, make sure that the inner flange and flange cover is located correctly on the motor shaft as shown in (Fig. J4 & J5).

- Align the drive shaft with the screw hole of the trimmer head, and then retighten the trimmer head onto the shaft COUNTERCLOCKWISE.

- Rotate the trimmer head to align the slot in the flange with the shaft-locking hole in the gear case and insert the provided hex key into the aligned holes to act as a stabilizer.

- Wear gloves. Securely tighten the trimmer head onto the shaft COUNTERCLOCKWISE (Fig. J6).

REPLACE THE BRUSHCUTTER GUARD WITH THE STRING TRIMMER GUARD

- Remove the brushcutter guard by loosening the two bolts. Then remove the bolts, washers, and guard (Fig. K1). Keep the guard in a safe place for future use.

- Lift the string trimmer head and face it downward. Align the two mounting holes in the guard with the two assembly holes in the base of the shaft. Make sure that the internal surface of the guard faces toward the string trimmer head (Fig. K2).

- Install the strimmer guard included in the EGO kit AH3810 with the two bolts and washers from the brushcutter (Fig. K2).

- Use the supplied hex key to tighten the bolts.

WARNING: USING WITH TRIMMER HEAD (EGO KIT AH3810, SOLD SEPARATELY)

To avoid serious personal injury, wear goggles or safety glasses at all times

when operating this unit. Wear a face mask or dust mask in dusty locations.

Clear the area to be cut before each use. Remove all objects, such as rocks,

broken glass, nails, wire, or string that can be thrown or become entangled in

the cutting attachment. Clear the area of children, bystanders, and pets. At a

minimum, keep all children, bystanders, and pets at least 15 m away; there

still may be risk to bystanders from thrown objects. Bystanders should be

encouraged to wear eye protection. If you are approached, stop the machine

immediately.

-

WARNING: To prevent serious personal injury, remove the battery pack from the machine before servicing, cleaning, changing attachments, or removing material from the unit.

The line-cutting blade on the guard can dull over time. It is recommended that you periodically sharpen it with a file or replace it with a new blade. -

WARNING: Always wear gloves when mounting or replacing the guard or when sharpening or replacing the line-cutting blade. Note the location of the line-cutting blade on the guard and protect your hand from injury.

-

WARNING: Never use water to clean your trimmer. Avoid using solvents when cleaning plastic parts. Most plastics are susceptible to damage from various types of commercial solvents. Use clean clothes to remove dirt, dust, oil, grease, etc.

ADJUSTING THE CUTTING LINE LENGTH (Fig.L)

The trimmer head allows the operator to release more cutting lines without

stopping the motor. As the line becomes frayed or worn, the additional line

can be released by lightly tapping the trimmer head on the ground while

operating the trimmer.

WARNING:

Do not remove or alter the line-cutting blade assembly. Excessive line length

will cause the motor to overheat and may result in serious personal injury.

TIPS FOR BEST TRIMMING RESULTS

- The correct angle for the cutting attachment is parallel to the ground. Do not force the trimmer. Allow the very tip of the line to do the cutting (especially along walls). Cutting with more than the tip will reduce cutting efficiency and may overload the motor.

- The cutting height is determined by the distance of the cutting line from the lawn surface.

- Grass over 20 cm should be cut by working from top to bottom in small increments to avoid premature line wear or motor drag.

- Slowly move the trimmer into and out of the area being cut, maintaining the cutting head position at the desired cutting height. This movement can be either a forward-backward motion or a side-to-side motion. Cutting shorter lengths produces the best results.

- Avoid trimming when grass and weeds are wet.

- Wire and picket fences can cause extra string wear or breakage. Stone and brick walls, curbs, and wood may wear strings rapidly.

- Avoid trees and shrubs. Tree bark, wood moldings, siding, and fence posts can easily be damaged by the strings.

LINE REPLACEMENT

Please refer to the “LINE REPLACEMENT” section in the manual for EGO kit

AH3810 (SOLD SEPARATELY).

MAINTENANCE

- WARNING: When servicing, use only identical replacement parts. Use of any other parts may create a hazard or cause product damage. To ensure safety and reliability, all repairs should be performed by a qualified service technician.

- WARNING: Battery-powered machines do not have to be plugged into an electrical outlet; therefore, they are always in operating condition. To prevent serious personal injury, take extra precautions and care when performing maintenance, service, or changing the cutting accessories or attachments.

- WARNING: To prevent serious personal injury, remove the battery pack from the machine before servicing, cleaning, or removing material from the unit. All brushcutter services, other than the items listed in these maintenance instructions, should be performed by competent brushcutter service personnel.

GENERAL MAINTENANCE

Avoid using solvents when cleaning plastic parts. Most plastics are

susceptible to damage from various types of commercial solvents and may be

damaged by their use. Use a clean cloth to remove dirt, dust, oil, grease,

etc.

WARNING:

When cleaning the machine, DO NOT immerse it in water or other liquids.

CLEANING

- Remove the battery pack.

- After each use, clean the debris, clogged soil, grass on the blade or the guard, or the grass that may have wrapped itself around the motor shaft or trimmer head with a soft brush.

- Wipe the machine surface with a clean cloth moistened with a mild soap solution.

- Use a small brush or a vacuum cleaner to clean the air vents on the rear housing. Keep the air vents free of obstructions.

- Do not use any strong detergents on the plastic housing or the handle. They can be damaged by certain aromatic oils, such as pine and lemon, and by solvents such as kerosene. Moisture can also cause an electric shock hazard. Wipe off any moisture with a soft dry cloth.

When the blade becomes dull or both edges of the blade are dull, please have it sharpened by a qualified service technician or replace it with a new one if necessary.

REPLACING THE BLADE

WARNING:

A worn, cracked, or damaged blade can break and pieces of the damaged blade

can become dangerous projectiles. Thrown objects can cause serious injury.

Inspect the blade regularly and do not operate the brushcutter with a worn or

damaged blade.

Use proper eye protection while removing, sharpening, and installing the blade.

To remove the blade

- Remove the battery pack.

- Rotate the outer flange to align the slot in the inner flange with the shaft-locking hole in the gear case and insert the included hex key into the aligned holes to act as a stabilizer described in steps 2 and 3 in the “MOUNTING THE BLADE” section.

- Position the gear case against a solid surface for support. Use one hand to grasp the blade and the other hand to loosen the nut in the direction of the arrow marked on the outer flange, using the included multi-function wrench. Remove the nut and the outer flange and save them for reassembly (Fig.M).

- Check and replace the inner flange and the flange cover if they are worn.

- Install the new blade onto the motor shaft in the order shown in Fig. N. For instructions, follow steps 5 – 7 in the “MOUNTING THE BLADE” section.

LUBRICATING THE DRIVE GEAR

- For best operation and longer lifetime, lubricate the brushcutter drive gear with a special grease as described below after every 50 hours of operation.

- There are two sealing screws: one on the gear case (Fig. O1) and the other on the power head (Fig. O2).

- Remove them with the provided hex key and follow the steps below to apply up to 5 ml of grease into the oil hole (Fig. O).

DO NOT FULLY FILL THE GEAR CASE WITH THE GREASE.

- Lay the brushcutter on its side so that the sealing screw to be removed is facing upwards (Fig. O1 & O2).

- Use the included hex key to loosen and remove the sealing screw.

- Use a grease gun (not included) to inject some grease into the oil hole; do not exceed 3/4 capacity.

- Tighten the sealing screw(s) after injection.

The grease should meet the following requirements:

- NLGI Grade Penetration: NLGI-1

- Thickener Type: Ester

- Recommended Operating Temperature Range: -40°C to 180°C

- Other than the above, the grease should also have excellent low-temperature startup, EP, mechanical shearing, abrasion resistance, and oxidative stability properties.

TRANSPORTING AND STORING

- If the 3-tooth blade is installed, always place its sheath on the blade before storing or transporting the machine. Use caution to avoid the sharp teeth of the blade (Fig. P).

- Clean the machine thoroughly before storing it.

- Store the machine indoors, in a dry place that is inaccessible to children.

- Keep away from corrosive agents such as garden chemicals and deicing salts.

PROTECTING THE ENVIRONMENT

- Do not dispose of electrical appliances as unsorted municipal waste, use separate collection facilities.

- Contact your local government for information regarding the collection systems available.

- If electrical appliances are disposed of in landfills or dumps, hazardous substances can leak into the groundwater and get into the food chain, damaging your health and well-being.

TROUBLESHOOTING

| PROBLEM | CAUSE | SOLUTION |

|---|---|---|

| The machine will not start or stop working | ◾ The battery pack is not | |

| attached to the machine. | ◾ Attach the battery pack to the machine. | |

| ◾ No electrical contact between the machine and the battery pack. | ◾ |

Remove the battery, check contacts, and reinstall the battery pack until it

snaps into place.

◾ The battery pack charge is depleted.| ◾ Charge the battery pack.

◾ The lock-off lever and trigger switch are not depressed simultaneously.|

◾ Move the lock-off lever up and press the trigger switch at the same time.

◾ The battery is too hot. See the chapter “Battery High- Temperature

Protection”.| ◾ Remove the battery pack and cool the battery pack until the

temperature drops below 67°C.

◾ The brushcutter is too hot. See the chapter “Machine High-Temperature

Protection”.| ◾ Remove the battery pack and cool the brushcutter until the

temperature drops below 80°C.

◾ The motor is overloaded. See the chapter “Machine Overload Protection”.

| ◾ The motor will recover when the load is removed. For continuous work,

decrease the load on the brushcutter, and avoid cutting heavy/ woody shrubs,

or oversized cutting lines (when the machine is used as a string trimmer).

Excessive vibration or noise.| ◾ The grease in the gear case is nearly run

out.| ◾ Lubricate the drive gears in the gear case, refer “LUBRICATING THE

DRIVE GEAR” section in this manual.

When trimming, the trimmer head will not advance the line.| ◾ The motor

shaft or trimmer head is bound with grass.| ◾ Stop the machine, remove the

battery, and clean the motor shaft or the trimmer head thoroughly.

◾ There is not enough line on the spool.| ◾ Remove the battery and

replace the new cutting line, follow the section “ LINE REPLACEMENT ”

in the manual for EGO kit AH3810.

◾ Line is tangled in the trimmer head.| ◾ Remove the battery, reload the

cutting line, and follow the section “ LINE REPLACEMENT ” in the manual

for EGO kit AH3810.

◾ The line is too short| ◾ Remove the battery and pull the lines while

alternately pressing down on and releasing the bump head.

When trimming, grass wraps around the trimmer head.| ◾ Cutting tall grass

at ground level.| ◾ Cut tall grass from the top down, removing no more than

8 inches (20 cm) in each pass to prevent wrapping.

---|---|---

When trimming, the line-cutting blade on the guard cannot cut the line| ◾

The line-cutting blade has become dull.| ◾ Sharpen the line-cutting blade

with a file or replace it with a new blade.

WARRANTY POLICY

For warranty service or to make a claim, please visit our Warranty Portal at egopowerplus.com.au/warranty-policy, alternatively you can contact EGO customer service via the following, Australia 1300 000 346, New Zealand 0508 000 346.

Chevron Australia Pty Ltd ABN 36 165 077 501 and Chevron New Zealand Subsidiary Ltd NZBN 9429049277616 (“Chevron”) warrants to the original domestic purchaser that this product will be free from defects in materials and workmanship for 5 years from the date of purchase, and any battery or charger will be free from defects in materials and workmanship for 3 years from the date of purchase. The warranty for commercial use is 1 year on all products, batteries, and chargers. The Commercial Range Product Warranty for commercial users is 2 years for a product, backpack battery (BAX1501), and commercial charger (CHX5500E). Please refer to the product warranty table below for further clarification. To make a claim, call 1300 000 346 for AU or 0508 000 346 for NZ or lodge a claim via our portal link above. Any handling and transportation costs (and other expenses incurred in claiming this warranty) are not covered by this warranty and will not be borne by Chervon. The replacement product or part or repaired product will be made available for your collection at an address nominated by Chervon. Where a valid warranty claim is made, Chevron will replace the defective product or repair the fault. Where the product is repaired, Chervon may use refurbished parts. This warranty does not cover normal wear and tear, misuse or abuse (including overloading of the product beyond capacity and exposure to water or rain), accidents, neglect or lack of proper installation, and improper maintenance or storage. This warranty does not cover the damage resulting from modification, alteration or unauthorized repair. This warranty does not cover normal deterioration of the exterior finish, including but not limited to scratches, dents, paint chips, or any corrosion or discoloring by heat, abrasive, and chemical cleaners. This warranty is void if the product has been used for rental purposes. This warranty may also be further limited or voided as specifically detailed in the Product Manual. Chevron has no other liability under this warranty. The benefits to you given by this warranty are in addition to other rights and remedies imposed by State and Federal legislation that cannot be excluded. Our goods come with guarantees that cannot be excluded under the Australian Consumer Law and the New Zealand Consumer Guarantee Act 1993. You are entitled to a replacement or refund for a major failure and compensation for any other reasonably foreseeable loss or damage. You are also entitled to have the goods repaired or replaced if the goods fail to be of acceptable quality and the failure does not amount to a major failure. The warranty applies to the original purchaser and applies only to purchases made from authorized EGO Dealers, which can be confirmed on the website store locator. For the avoidance of doubt, 3rd party online stores such as eBay, Gumtree, Amazon, etc. are excluded.

- Chervon Australia Pty Ltd, Unit 14, 5 Kelletts Rd, Rowville, VIC. 3178.

- Ph Australia; 1300 000 346. Email: support@egopowerplus.com.au.

- Chevron New Zealand Subsidiary Ltd, 4th Floor, Smith & Caughey Building, 253 Queen St, Auckland, 1141.

- Ph New Zealand; 0508 000 346. Email: support@egopowerplus.co.nz.

PRODUCT WARRANTY TABLE

PRODUCT OR MODEL #| LIMITED WARRANTY FOR CONSUMER USE (PERSONAL, HOUSEHOLD USE)| LIMITED WARRANTY FOR PROFESSIONAL USE (ANY COMMERCIAL, AGRICULTURAL, INSTITUTIONAL,

OR INCOME-PRODUCING USE)

---|---|---

EGO Power+ Outdoor Power Equipment and Portable Power Products| 5 years| 1

year

EGO Power+ Battery Packs and Chargers| 3 years| 1 year

Specific warranties apply to the products below:

Commercial Tools: LBX6000, BCX3800, STX3800, HTX7500, CSX3000, PPX1000,

PSX2500, PTX5100, BHX1001, STX4500, BCX4500, EDX2000, HTX5300-P, HTX5300-PA,

LBPX8000| 5 years| 2 years

Commercial Backpack Battery: BAX1501| 3 years| 2 years

Commercial Charger: CHX5500E| 3 years| 2 years

References

Read User Manual Online (PDF format)

Read User Manual Online (PDF format) >>